Vision Inspection Systems

Vision Inspection

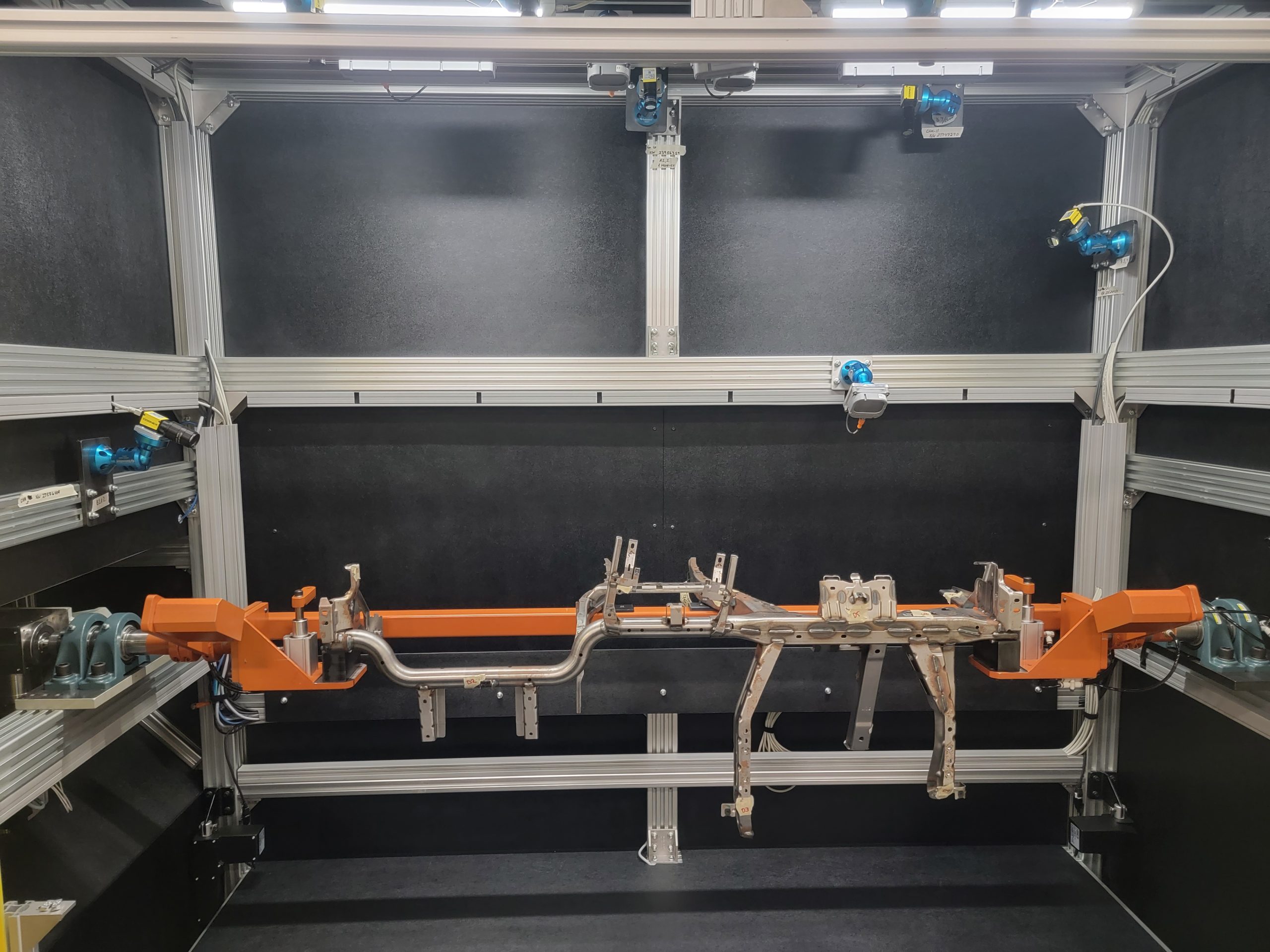

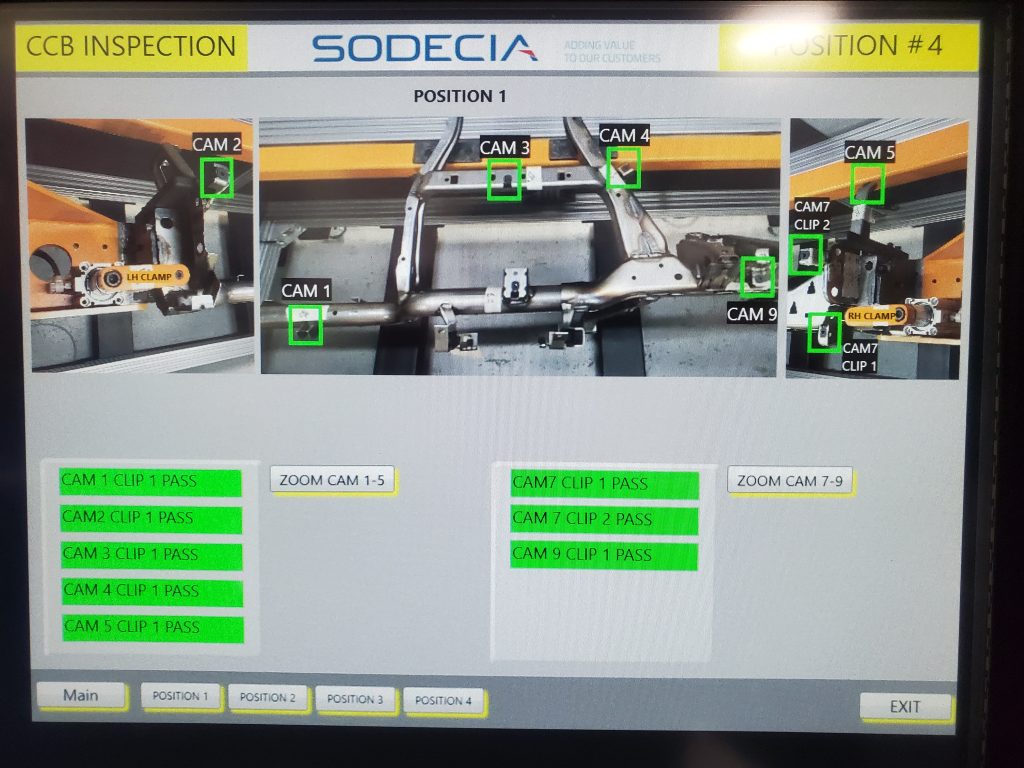

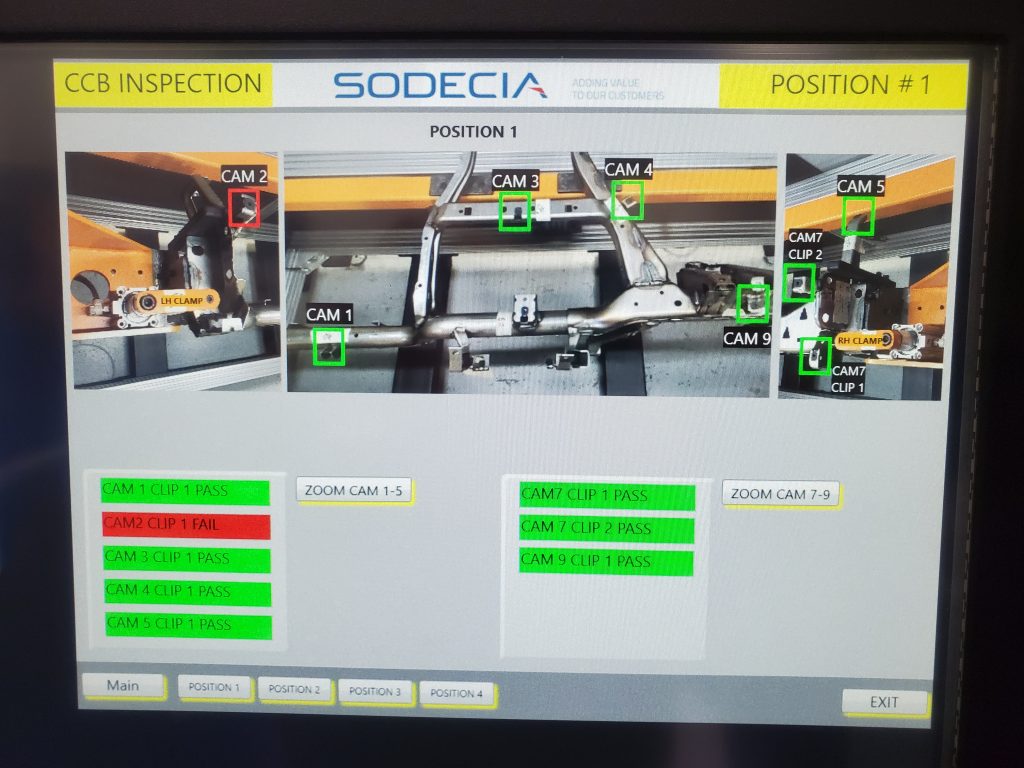

Our vision inspection systems are cutting-edge technologies designed to automate quality control and ensure the precision of your production processes. By leveraging high-resolution cameras and advanced software algorithms, our systems can detect defects, measure dimensions, and verify component placement with remarkable accuracy. Vision inspection plays a crucial role in improving product quality, minimizing waste, and reducing the need for manual inspections. With our solutions, you can maintain consistently high standards and enhance the efficiency and reliability of your production lines.

One of the key advantages of our vision inspection systems is their ability to detect defects that are often undetectable to the human eye. Whether it’s spotting scratches, misalignments, or missing components, our systems can quickly identify these issues before they affect the rest of the production process. This early detection ensures that defective products don’t make it to the customer, saving valuable time and resources that would otherwise be spent on rework or returns. Our systems also help your business meet strict industry standards and regulations, ensuring that products are manufactured to exact specifications every time.

In addition to quality control, our vision inspection systems excel at automating measurements and verifying the accuracy of parts and assemblies. They can measure key parameters such as size, shape, color, and orientation, ensuring that each component adheres to strict tolerances. By automating these tasks, our systems eliminate human error and significantly increase the speed of your production process. With the high-speed capabilities of our vision systems, they’re ideal for high-volume manufacturing environments where both efficiency and precision are essential.

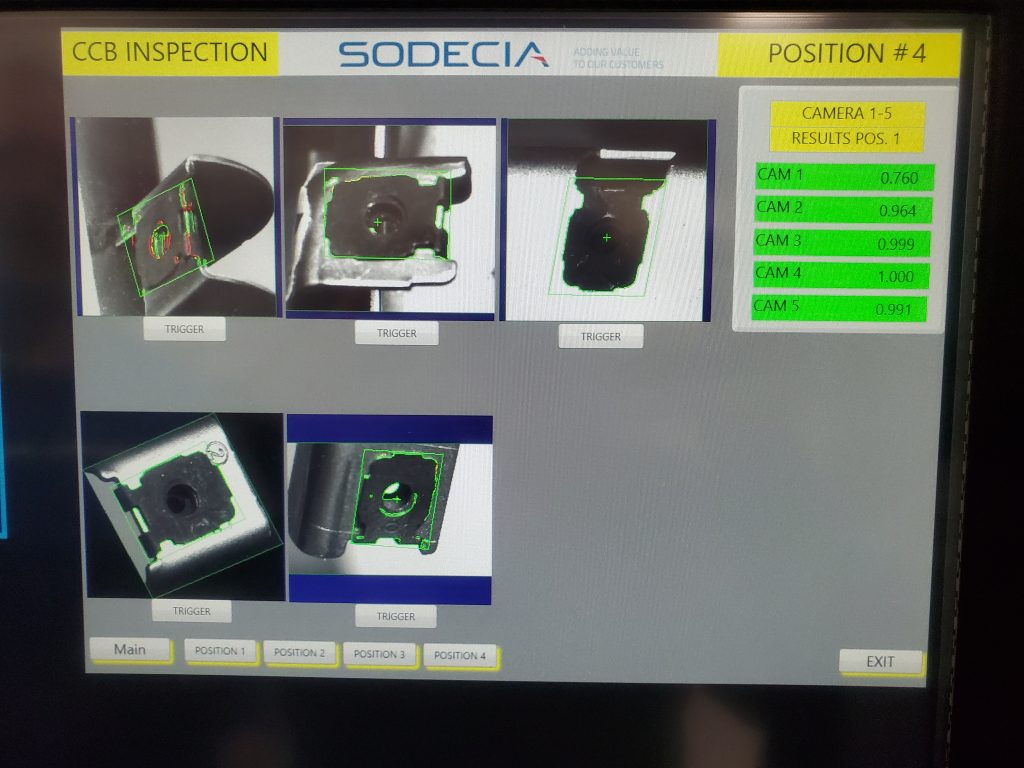

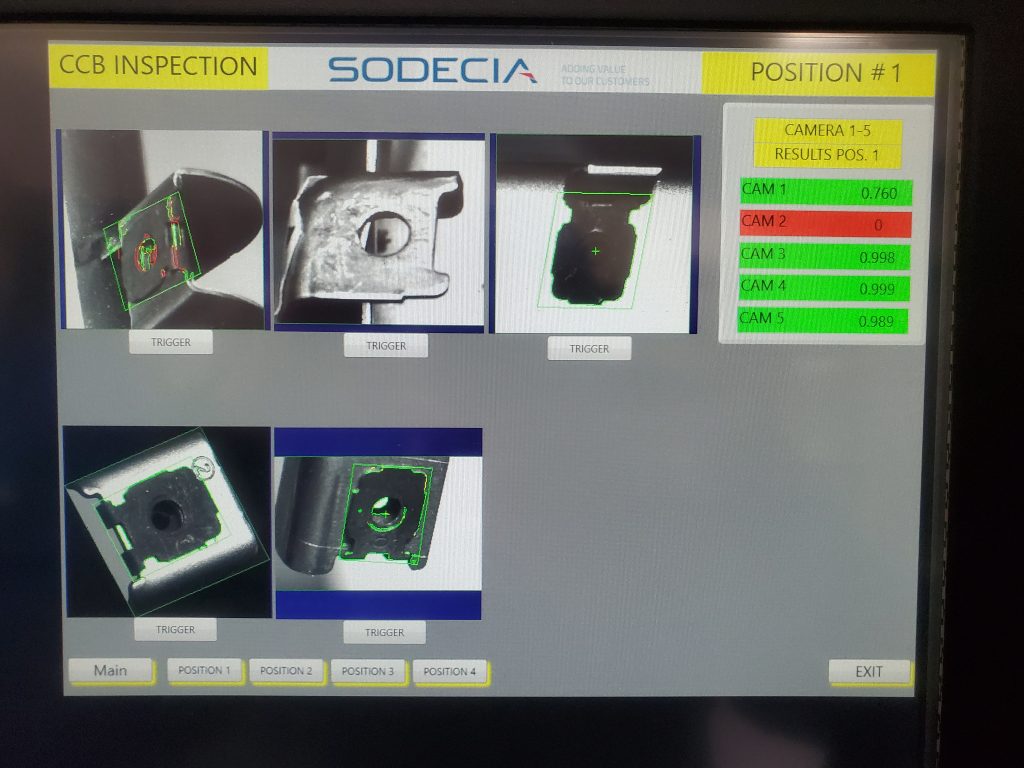

Door Panel Lockout Fixtures with Integrated Vision System

Our high-precision door panel lockout fixture with integrated vision system, is designed to streamline the inspection of RH and LH automotive door panels. Built on durable 4″ x 4″ steel tubing and featuring black-coated base plates to enhance vision accuracy, these single-station fixtures ensure reliable part placement and secure clamping through sensor-activated controls and a two-hand tie-down system.

Each fixture is equipped with an advanced Omron vision system, utilizing up to four cameras, specialized lighting, and a vision controller to detect defects such as missed cutouts or holes. The integrated Allen Bradley PLC and HMI panel provide real-time feedback to operators, clearly displaying pass/fail results and highlighting any problem areas directly on screen. Optional features like light curtains and paint marker systems further enhance safety and traceability.

These fixtures reflect Automated Solutions’ commitment to quality and innovation in manufacturing automation. Designed for ease of integration, operator training, and long-term reliability, they offer manufacturers a robust, cost-effective solution for maintaining high inspection standards across multiple door panel types.

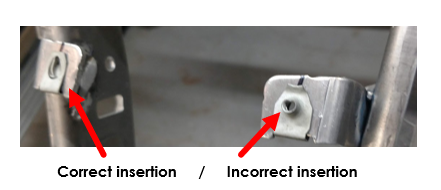

Clip Presence Detection

Test Pass

Test Fail

Clip Present

Clip Missing

Stay up to date with our expert advice and discover how automation can boost efficiency.