Automated Drilling

Automated Drilling Machines

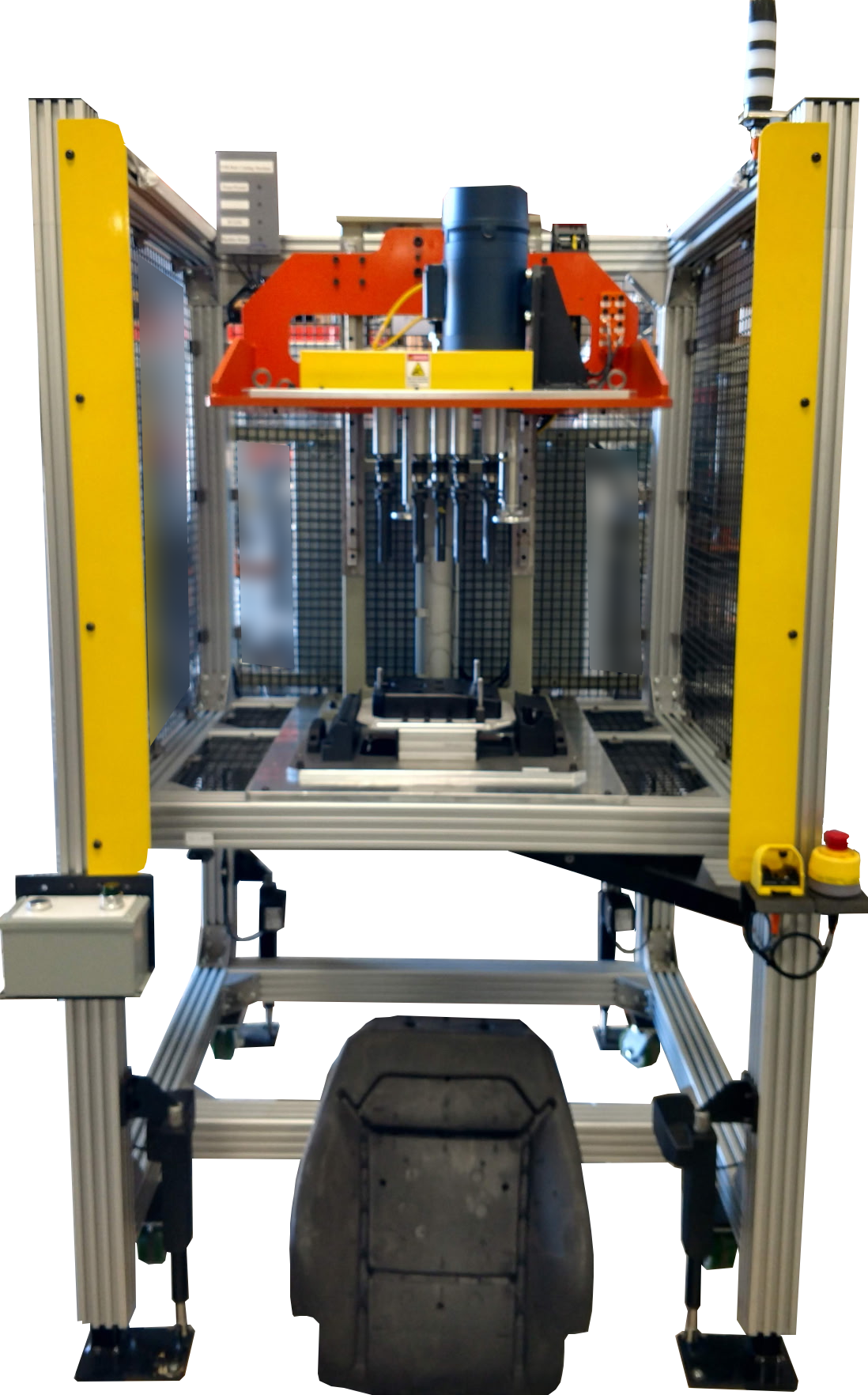

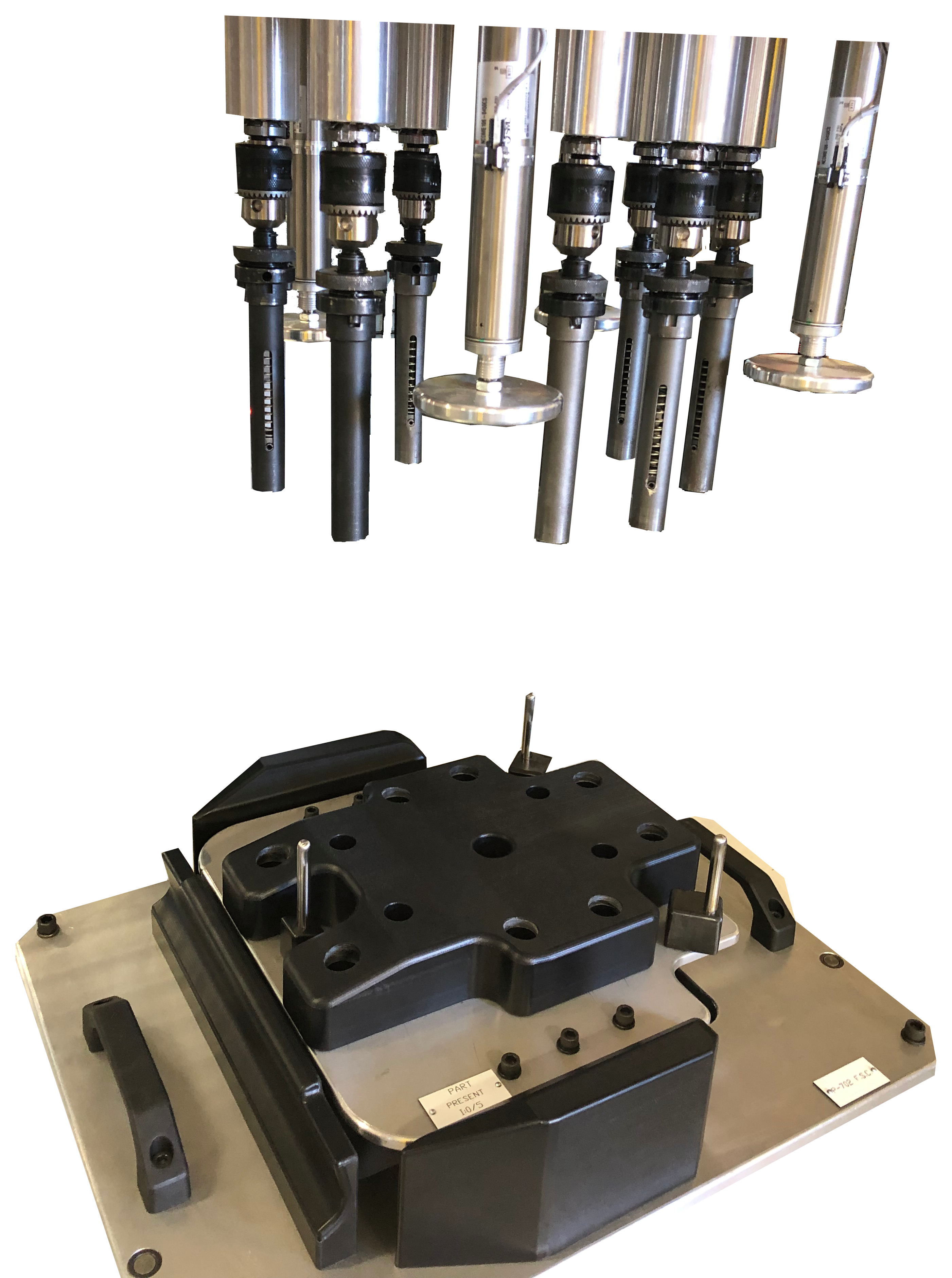

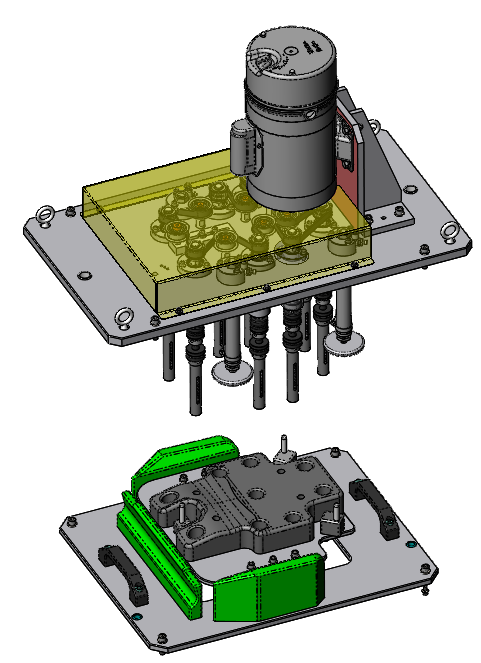

Designed to deliver precise, efficient, and repeatable results in manufacturing environments where consistency and operator safety are paramount. One of our standout offerings, the seatback vent Hole Cutting Fixture, showcases our ability to design highly specialized equipment tailored to customer specifications. This machine features a robust aluminum extrusion frame and CNC-cut nests that replicate the B-surface of foam components, ensuring accurate and repeatable positioning for hole cutting operations.

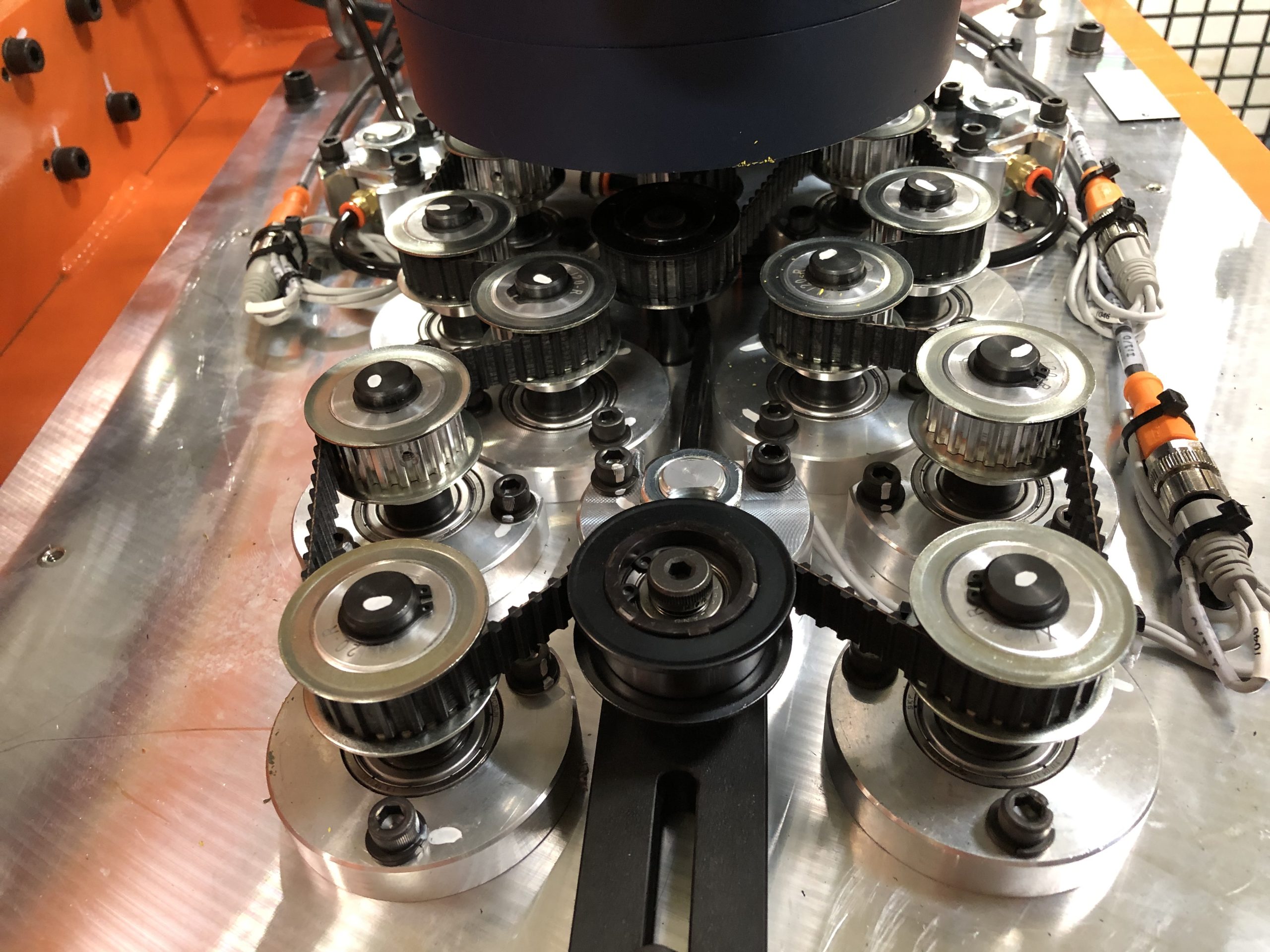

Equipped with a custom multi-spindle tooling head, the system allows simultaneous drilling using multiple spindles, all driven by an AC motor and serpentine belt for smooth operation. Quick-change features on each spindle, along with spring-loaded foam ejectors, streamline the process and minimize downtime. An integrated slug collection system efficiently channels waste foam into a collection box, maintaining a clean and organized workspace. Safety is built into the design, with light curtains protecting the operator and heavy-duty mesh guarding securing all other access points.

The machine’s control system includes an Allen-Bradley PLC, complete with a full set of safety and operational controls—such as emergency stop buttons, selector switches, and a lockable disconnect. Operator ergonomics are also considered, with adjustable-height jacks and overhead lighting included as standard. Engineered for flexibility and long-term durability, Automated Solutions’ drilling machines are ideal for high-volume applications that demand precision and safety without compromising on cycle time or maintenance ease.

Gallery

Stay up to date with our expert advice and discover how automation can boost efficiency.