Build Pallets

About 1st Row Seating Pallets

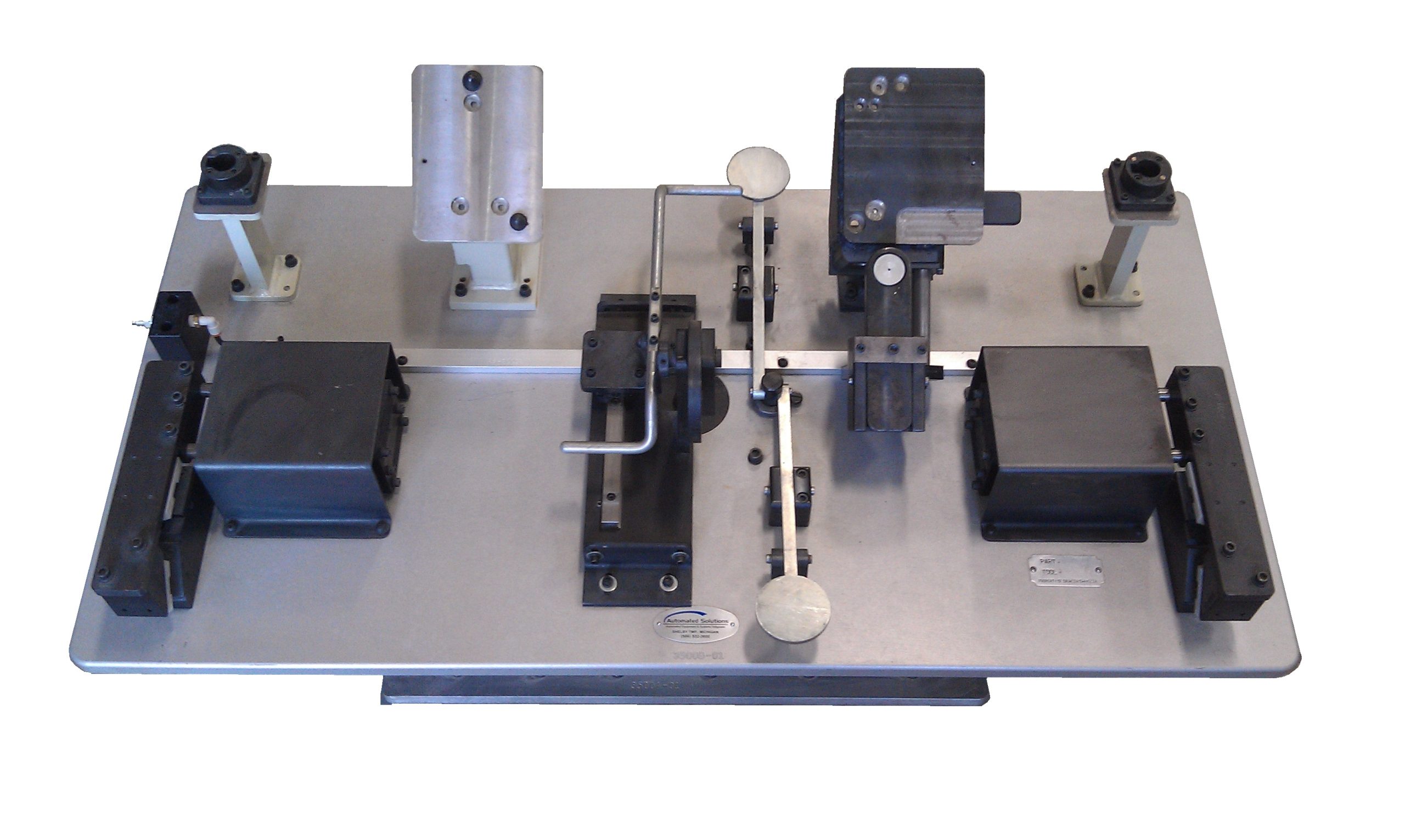

The First Row Build Pallet Tooling is a specialized assembly platform developed for the precise construction of first-row driver and passenger seats. Designed in house by Automated Solutions, Inc., this system offers a unified pallet tooling solution that supports both left-hand (LH) and right-hand (RH) seat variants using the same top tooling. Each seat is secured through ASI’s proven Integrated Pin and Latch Assembly, which provides a reliable, robust clamping method by engaging the seat track mounting holes. This ensures that both seat types are held securely in their vehicle design position at a 4° angle during assembly, allowing consistent build quality and seamless integration on the manufacturing line.

Each tooling unit is mounted to a standard Tekno combo base pallet and utilizes a custom aluminum U-plate. To accommodate both production and prototype stages, the system includes removable manual toggle clamps for manual operations during development. These clamps can be easily removed when transitioning to full production, where auto-unlock functionality becomes active via dedicated unlock stations at each conveyor line’s start and end. This auto-unlock system uses air cylinders and spring-loaded plungers to disengage the integrated latches, allowing for automated seat loading and unloading.

Built for flexibility and ease of maintenance, each pallet includes rotate-assist handles, build ticket clips, and is designed to clear all seating plastic track covers. The system is engineered to ensure high reliability, operator safety (with no exposed pinch points), and straightforward integration into existing manufacturing environments.

2nd and 3rd Row Pallets

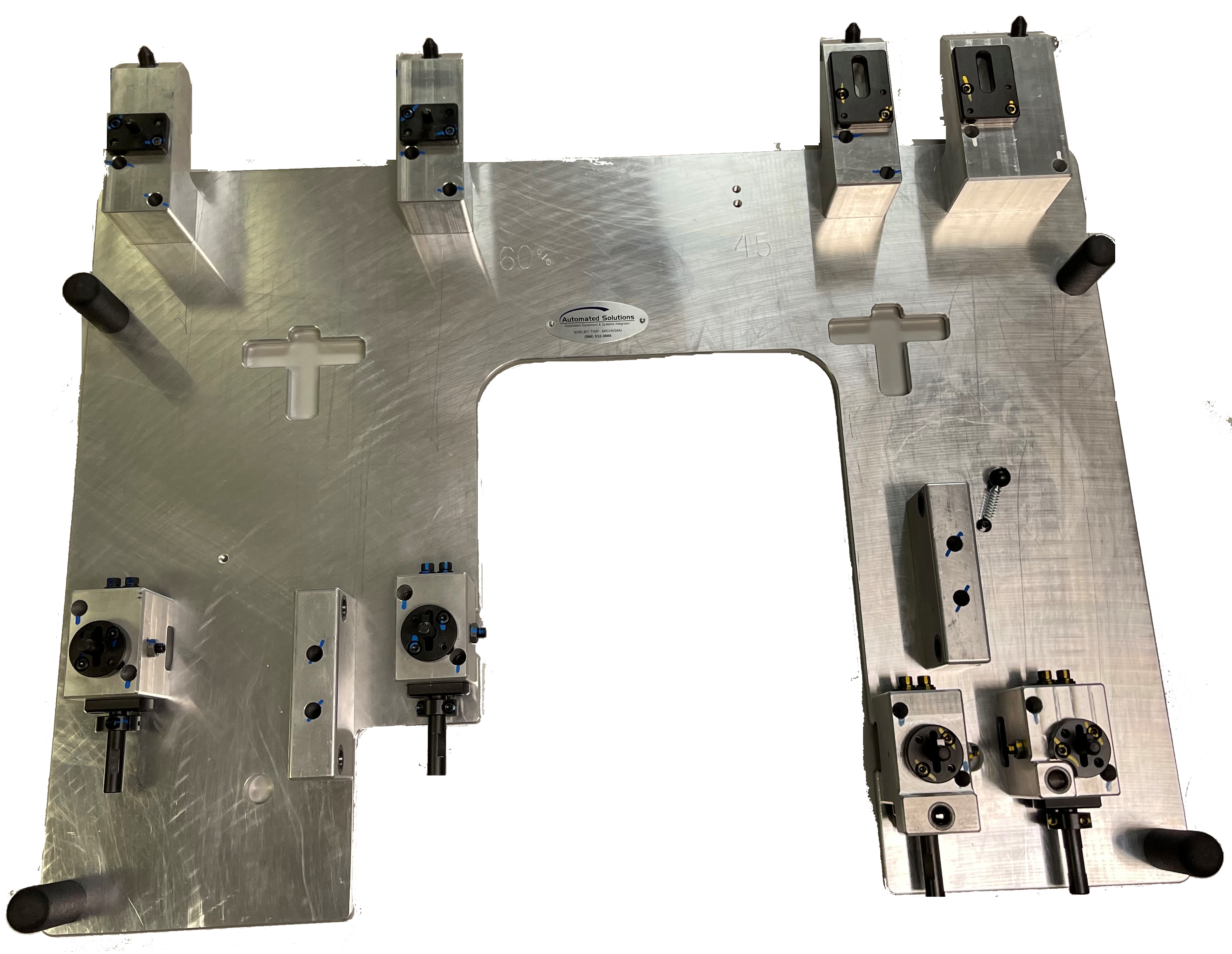

Second Row Build Pallet Tooling is a specialized assembly platform engineered to support the production of complete second-row seatback systems. This pallet tooling can be designed for a single seat configuration that includes two marriage brackets and three seatback components: RH 40%, LH 40%, and LH 20%. Or as seperate 40% LH/RH Pallets. The system ensures that each component is fixtured in its exact vehicle design position, enabling precise and repeatable builds. The static pallet tooling delivers a stable foundation while maintaining compatibility with existing online pallet base systems.

At the heart of the system is ASI’s Integrated Pin and Latch Assembly, a proven mechanism used to secure the marriage brackets in place. These latches engage automatically through holes in the track brackets, locking the seatbacks firmly during assembly.

The tooling is designed with nylatron tooling elements protect sensitive pivot bushings from damage. The design also supports manual loading of internal pin shafts into the marriage brackets without additional tooling for some seat elements. With production readiness in mind, the pallet system is built with minimal exposed pinch points and is designed to be easily serviceable. A complete spare parts list, layout drawing, and preventative maintenance schedule are provided upon project completion, ensuring smooth implementation and long-term reliability.

1st Row Pallets

2nd Row Pallets

3rd Row Pallets

Stay up to date with our expert advice and discover how automation can boost efficiency.