Clip Driving &

Tab Bending Machines

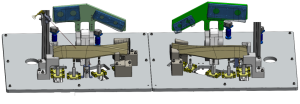

Clip Driving

A standout feature of our clip driving machines is their precision in clip placement. Thanks to our state-of-the-art vision verification systems and custom clip insert tools, each clip is inserted with exceptional accuracy, minimizing defects and ensuring top-notch product quality. Additionally, our machines use urethane clamping to securely hold components during insertion, preventing any damage to delicate materials. This combination of technology and design results in fewer reworks, consistent output, and reliable performance on every production run.

Our clip driving machines also offer a significant boost in productivity. By automating the clip insertion process, operators are free to focus on more complex tasks, maximizing the value of their time and expertise. The machines work at much higher speeds than manual labor, increasing throughput and enabling businesses to meet tight deadlines. With the ability to detect both metal and plastic clips, our machines ensure the right component is used for each application, reducing material waste and improving resource efficiency. This means higher production rates without compromising on quality.

In addition to improving productivity, our machines are designed with ergonomics in mind, reducing operator fatigue and enhancing workplace safety. Manual clip insertion can be physically taxing, but our machines minimize manual handling and repetitive motions, resulting in a more comfortable and efficient work environment. This design not only helps prevent worker strain but also reduces labor costs by decreasing the need for manual intervention. By increasing efficiency, reducing fatigue, and cutting labor costs, our clip driving machines provide a comprehensive solution for businesses looking to stay competitive in today’s fast-paced industries.

Tab Bending

Our custom tab bending machines are engineered to automate the tab bending process, ensuring each tab is securely and consistently formed. By integrating advanced automation and robotics, these machines virtually eliminate damaged or defective parts, significantly boosting productivity while minimizing operator fatigue. Features such as adjustable tooling allow for precise customization to various specifications, enhancing overall production efficiency.

Incorporating urethane or UHMW CNC-cut nesting optimizes material utilization, reducing waste and lowering production costs. The integration of vision verification systems ensures real-time quality control, maintaining high standards throughout the manufacturing process. Designed with improved ergonomics, our machines reduce the need for manual intervention, enhancing operator safety and comfort. This reduction in manual handling also leads to decreased labor costs, contributing to a more cost-effective production environment.

By automating complex bending sequences, our tab bending machines deliver exceptional precision and consistency, ensuring that each part meets stringent specifications and dimensional tolerances. This automation not only increases production rates but also enhances workplace safety by reducing the risk of human error and physical strain associated with manual bending operations. Integrating our machines into your production line offers a comprehensive solution to optimize efficiency, quality, and cost-effectiveness in your manufacturing processes.

Gallery

Stay up to date with our expert advice and discover how automation can boost efficiency.