Fiberglass Machines

The Fiberglass Winding Machine

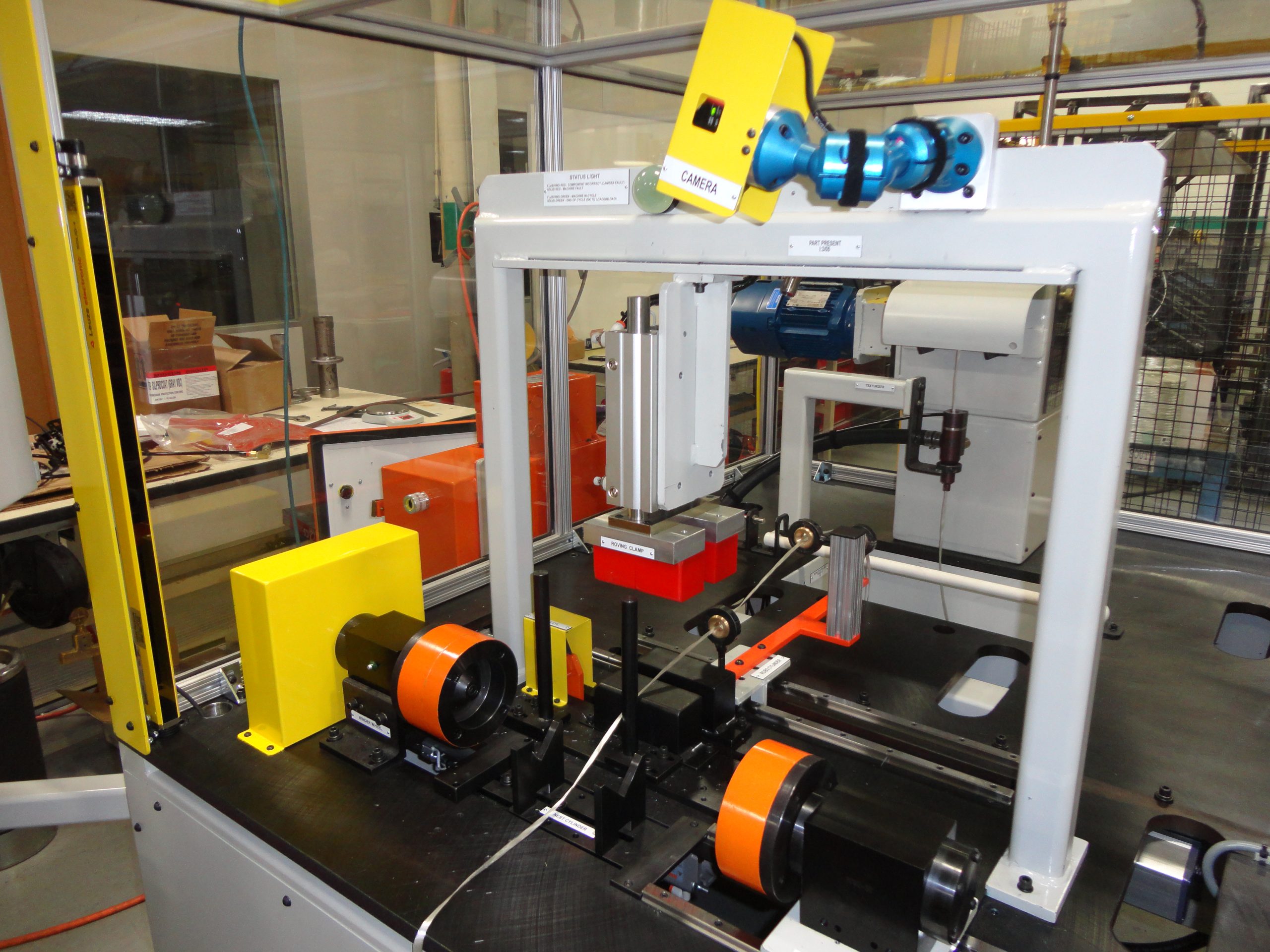

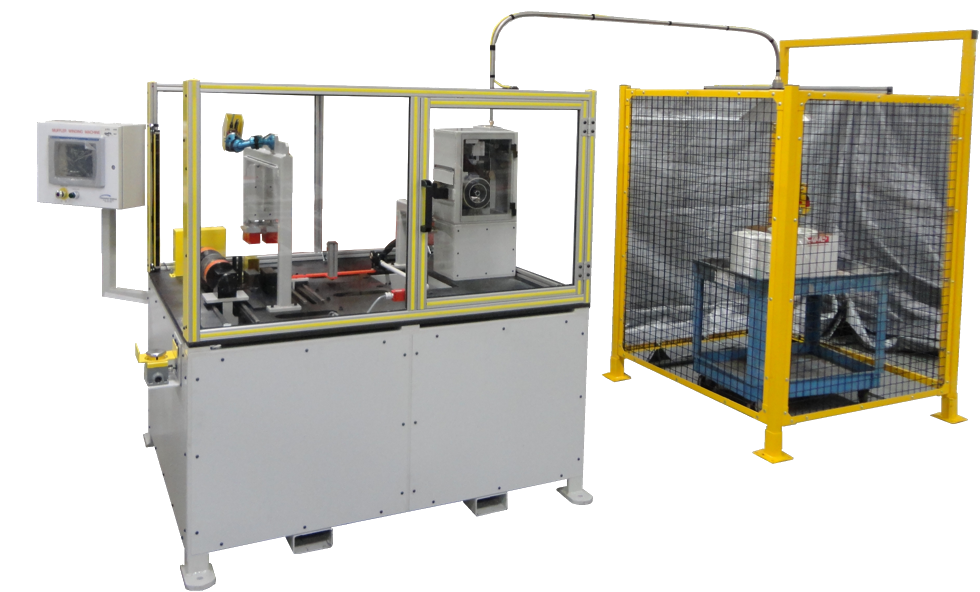

At Automated Solutions, Inc., we pride ourselves on delivering high-performance equipment tailored to the needs of the automotive industry. Our Fiberglass Winding Machine is specifically designed for texturized glass winding applications in muffler production. With a durable 2” square tube frame and state-of-the-art automation components, this machine combines robust construction with precise control to ensure consistent product quality and streamlined operation.

The Fiberglass Winding Machine allows for efficient and uniform wrapping of Advantex or E-glass fiberglass onto exhaust tubes. Operators simply load the tube into the machine, secure the fiberglass strand, and initiate the cycle with an intuitive finger-swipe start button. A high-performance Allen-Bradley CompactLogix PLC regulates motor speed based on glass accumulation, while a servo-driven linear actuator ensures smooth, even glass distribution along the length of the tube. Once winding is complete, the strand is cut and tucked, preparing the product for the next phase of manufacturing.

Several performance upgrades enhance the machine’s reliability and output speed. These include a processor upgrade, ceramic-to-bronze eyelet replacements for improved wear resistance, and a servo actuator for faster response and greater winding control. Compared to earlier models, the Fiberglass Winding Machine significantly reduces cycle time, with one configuration winding 140 grams of glass in under 42 seconds—optimizing throughput without sacrificing precision.

From advanced touch screen controls to integrated light curtain safety features, the Fiberglass Winding Machine is engineered for ease of use, safety, and productivity. Whether you’re manufacturing standard or custom muffler components, this machine is a smart investment in modernizing your production line. Contact us today to learn how the Fiberglass Winding Machine can elevate your manufacturing capabilities.

Direct Muffler Filling System

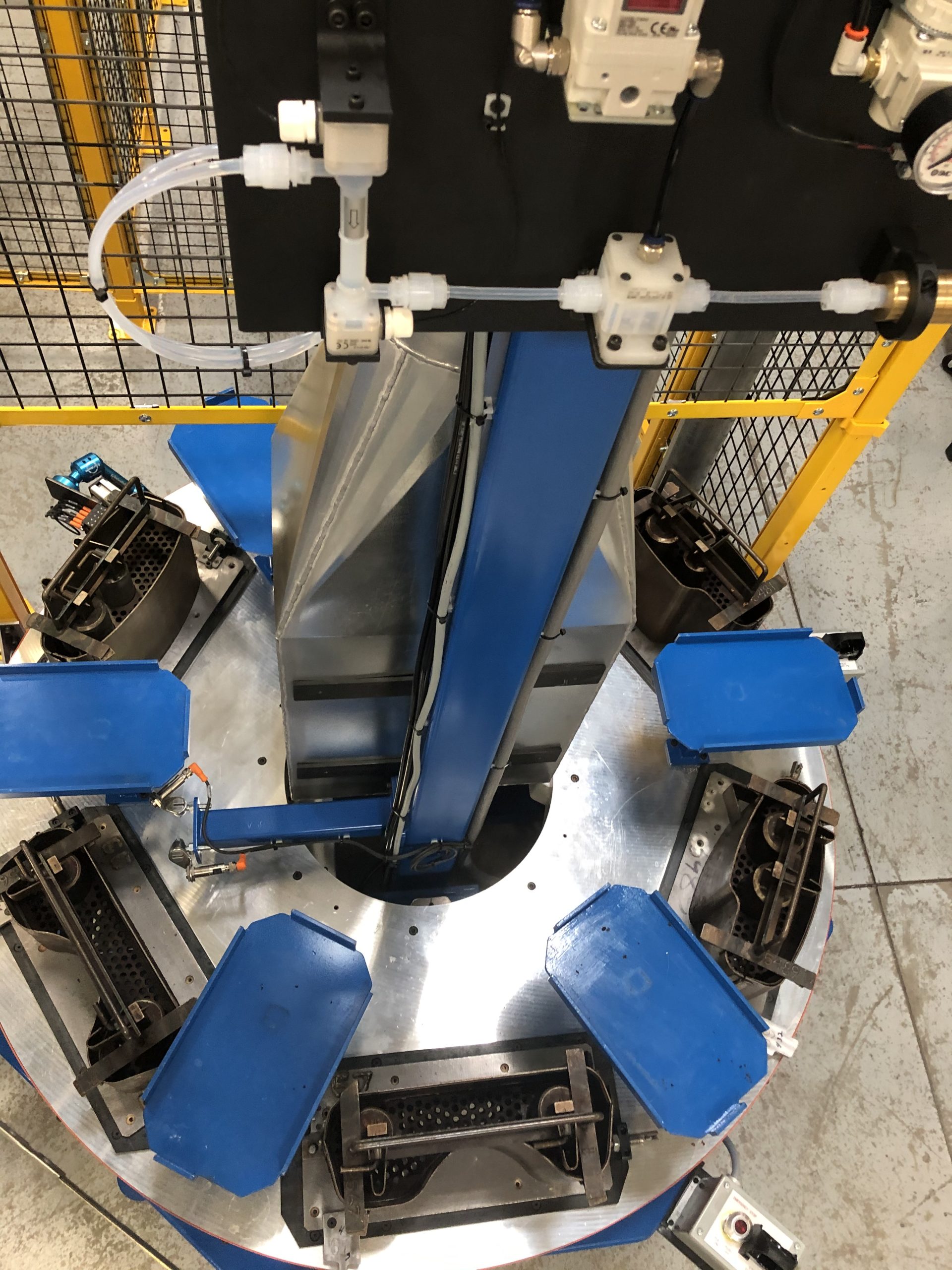

The system includes four core components: a dual-strand metering box, a vacuum-assisted filling turntable, a robot filling cell, and a creel pack safety cage. Fiberglass is pulled from the creel, metered with precision, and fed directly into the muffler by a robot-mounted nozzle. The two-station turntable enables continuous operation—while one muffler is being filled, the next can be loaded—maximizing throughput without compromising quality. Vacuum is applied internally via a plug-sealed perforated tube, drawing the strand evenly through the muffler core.

Safety and control are built into every aspect of the system. Fiber-optic sensors, light curtains, and interlocked doors ensure operator protection, while an Allen-Bradley CompactLogix processor with a 10” color touchscreen allows for recipe management, system diagnostics, and real-time feedback. The system is designed to accommodate multiple muffler styles with minimal tooling changes and supports recipe storage for flexible future expansion.

From enhanced operator safety to precision glass metering and fast cycle times, the Direct Muffler Filling System offers a high-performance, scalable solution for exhaust manufacturers. Contact Automated Solutions today to learn how this innovative system can help modernize your muffler production line with speed, consistency, and confidence.

Gallery

Stay up to date with our expert advice and discover how automation can boost efficiency.