Backframe and headrest stuffing

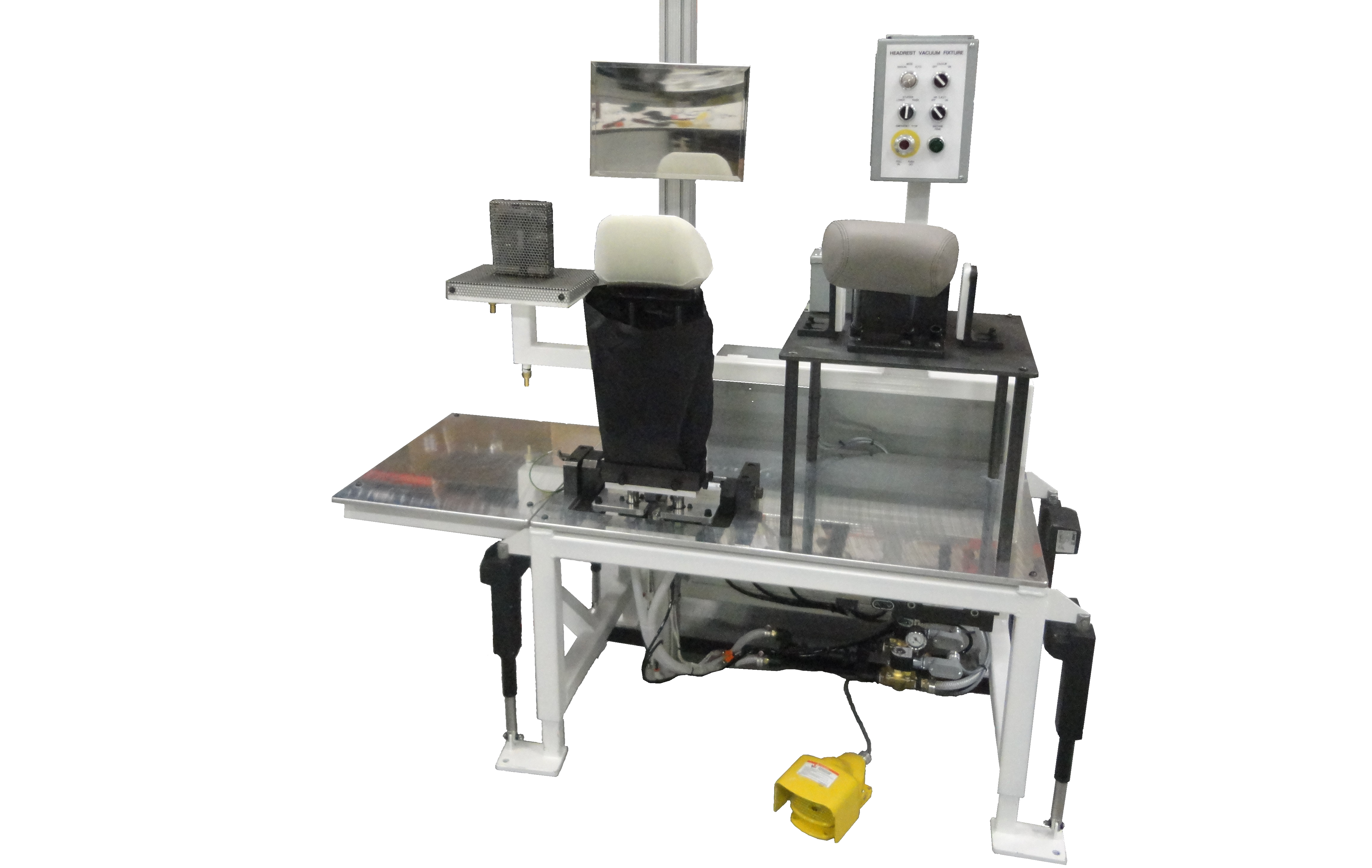

Vaccum Headrest Stuffing

Automated Solutions, Inc. offers a specialized Headrest Vacuum Fixture designed to streamline the headrest trim assembly process through the use of vacuum-assisted compression. Ideal for applications involving poly bag designs, this fixture effectively collapses the foam, making it easier for operators to apply and align trim covers. The vacuum tooling includes a pivoting head that can be manually adjusted between vertical and 45 degrees in 15-degree increments, providing ergonomic flexibility for operators across different working conditions.

Controlled by an Allen-Bradley PLC, the system includes manual operation features such as an auto/manual key switch and selector switches for enhanced control and ease of use. Though features like laser alignment and part presence sensors are not included in the base model, they are available as optional upgrades. Designed around a durable steel frame for structural integrity and cost efficiency, the Headrest Vacuum Fixture is a reliable and ergonomic solution for manufacturers seeking to improve trim assembly accuracy and throughput.

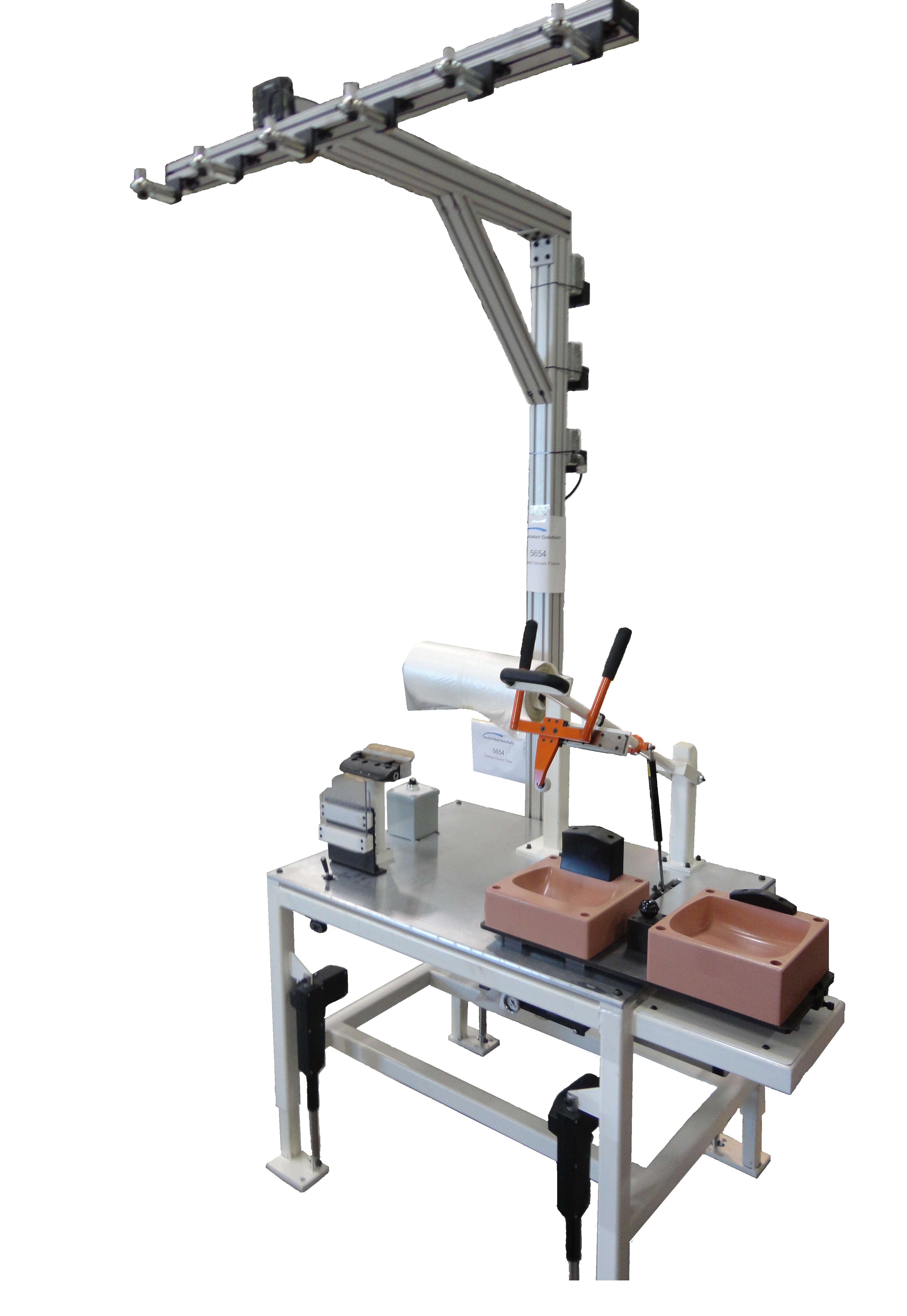

Bagless headrest stuffing saves waste by the use of a reusable bag. This compresses the foam eficiently and evenly for an easier process and less fatigue for the operator.

Bagless Headrest Stuffing

The fixture incorporates a secondary sub-station equipped with HDPE-lined angle brackets that securely hold the headrest during manual closeout. While the current configuration does not include an automated compression cylinder, it can be upgraded to meet evolving production requirements. A simple foot pedal controls the vacuum system, allowing the operator to manage foam compression and advancement through the poly bag with minimal effort. The tooling head is fabricated from hollow tubing to facilitate effective vacuum flow through the foam structure, ensuring consistent results.

Silk Bag Headrest Stuffing