Online Assembly Stations

Online Conveyor Assembly

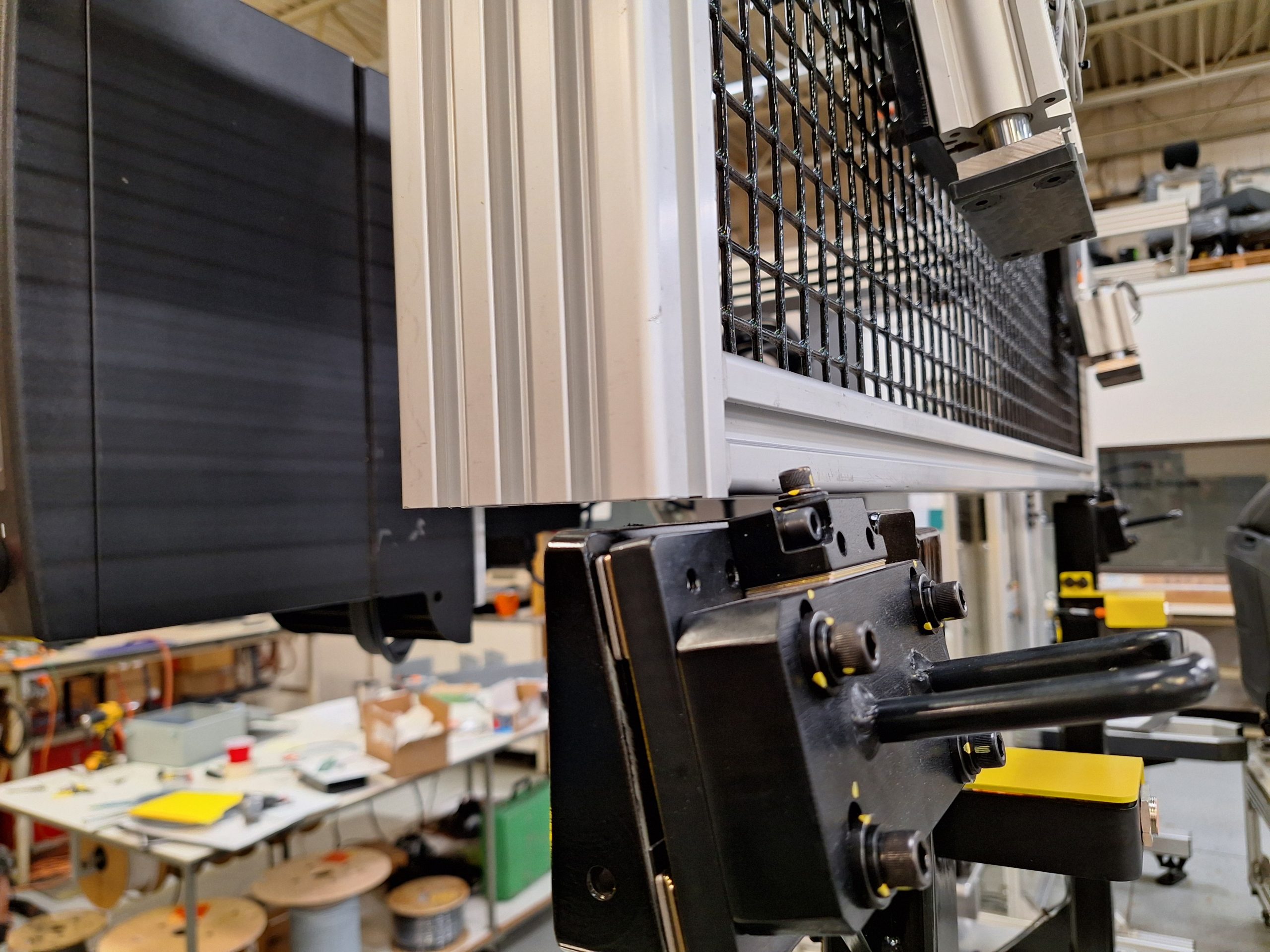

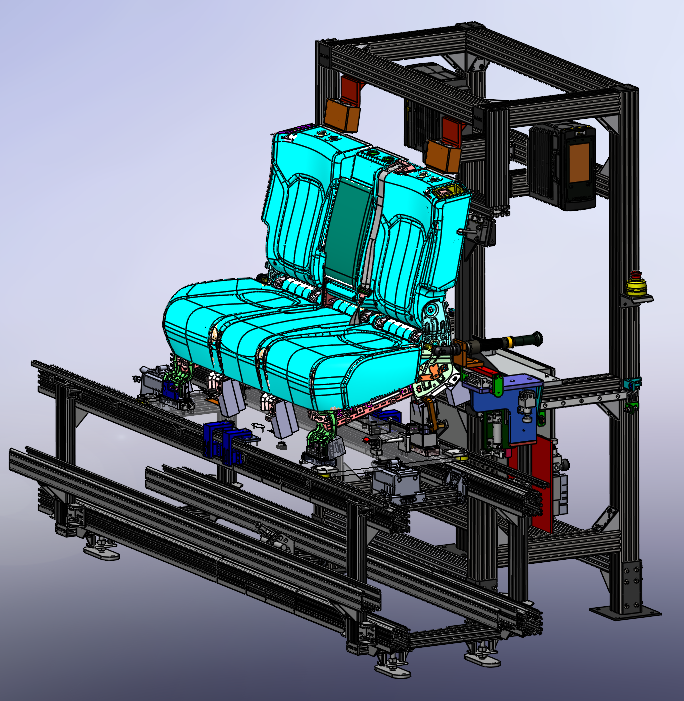

On-Line Conveyor Assembly Stations offer an efficient, integrated platform for streamlining seat assembly processes within high-volume automotive production lines. Designed to interface seamlessly with standard Tekno conveyor systems, our stations are built with durable aluminum extrusion framing and fixed-height alignment to ensure consistent compatibility with existing build lines. Key components like auto-unlock stations, integrated clamping mechanisms, and zero gravity torque arm assemblies allow for precision handling and secure assembly.

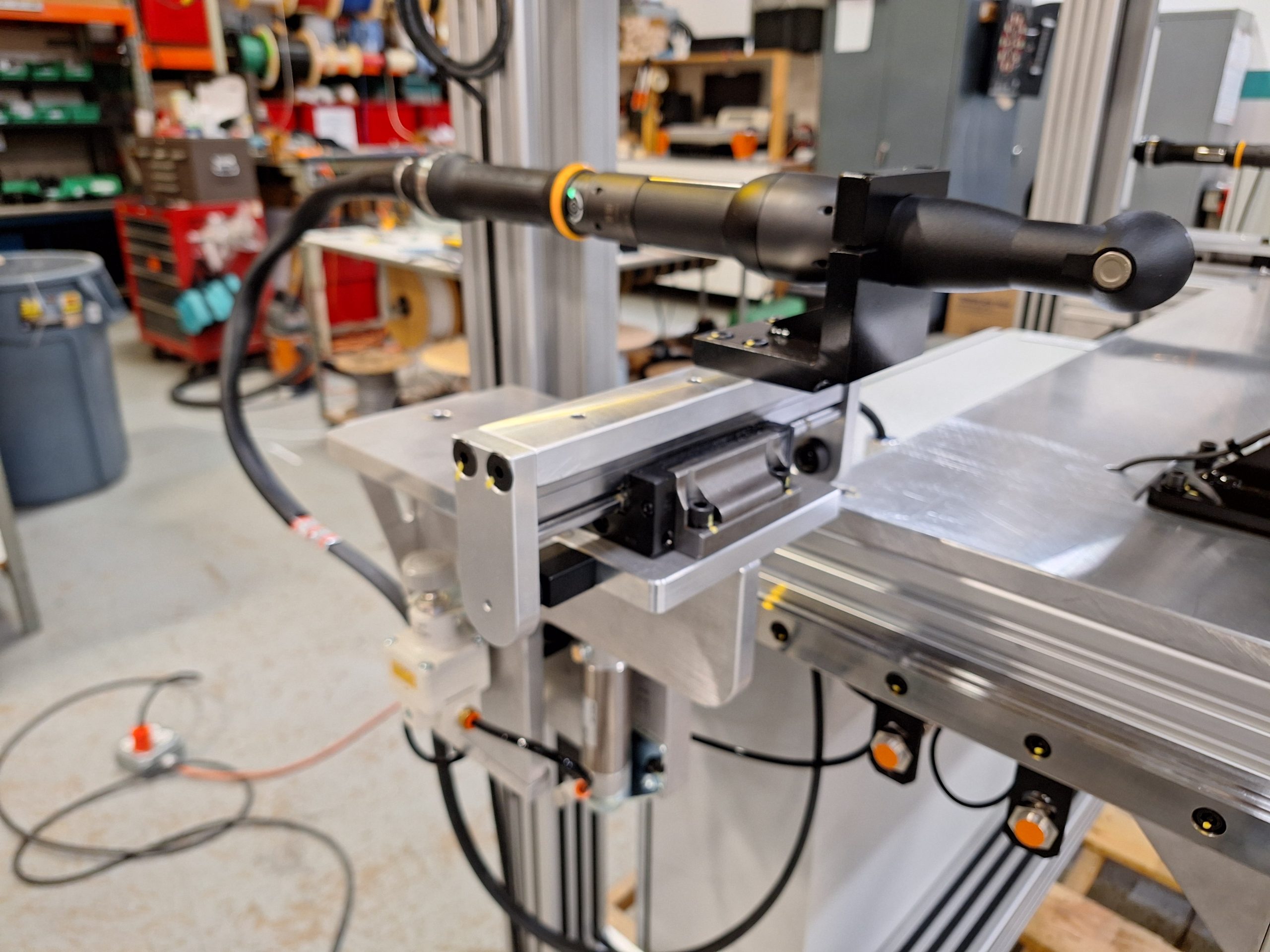

The assembly station incorporates advanced features including Allen-Bradley PLC control, a 10” PanelView Plus HMI with pivot mount for ergonomic access, and spatially-aware dual torque arms for accurate fastening operations. Sensor feedback throughout the station supports real-time validation of part presence, tool position, and torque verification—helping manufacturers reduce errors and increase quality assurance. Pneumatic clamping and manual slide tables provide the operator with controlled flexibility to manage parts during the assembly sequence and integrated software enable seamless data exchange for barcode scanning and label printing.

This modular station is ideal for manufacturers seeking to improve line efficiency without sacrificing quality or operator safety. With customizable tooling, optional manual or auto-unlock mechanisms, and compatibility with prototype or full-scale production builds, Automated Solutions delivers a future-ready platform that aligns with lean manufacturing principles. Whether retrofitting an existing system or designing a new assembly line, the On-Line Conveyor Assembly Station enhances operational performance and shortens cycle times.

Gallery

Seat Marriage Station

A fully automated On-Line Conveyor Assembly Station combines advanced robotics with integrated area scanning and safety fencing for hands-free operation. The system uses programmable logic controls, torque tools, and proximity sensors to perform precise assembly tasks without manual intervention. Safety scanners and fencing ensure compliance with industrial safety standards by preventing access during active cycles. This solution maximizes throughput, reduces labor requirements, and delivers consistent, high-quality results in demanding production environments.

Stay up to date with our expert advice and discover how automation can boost efficiency.