Piston Banding Machine

Piston Seal Banding Machine

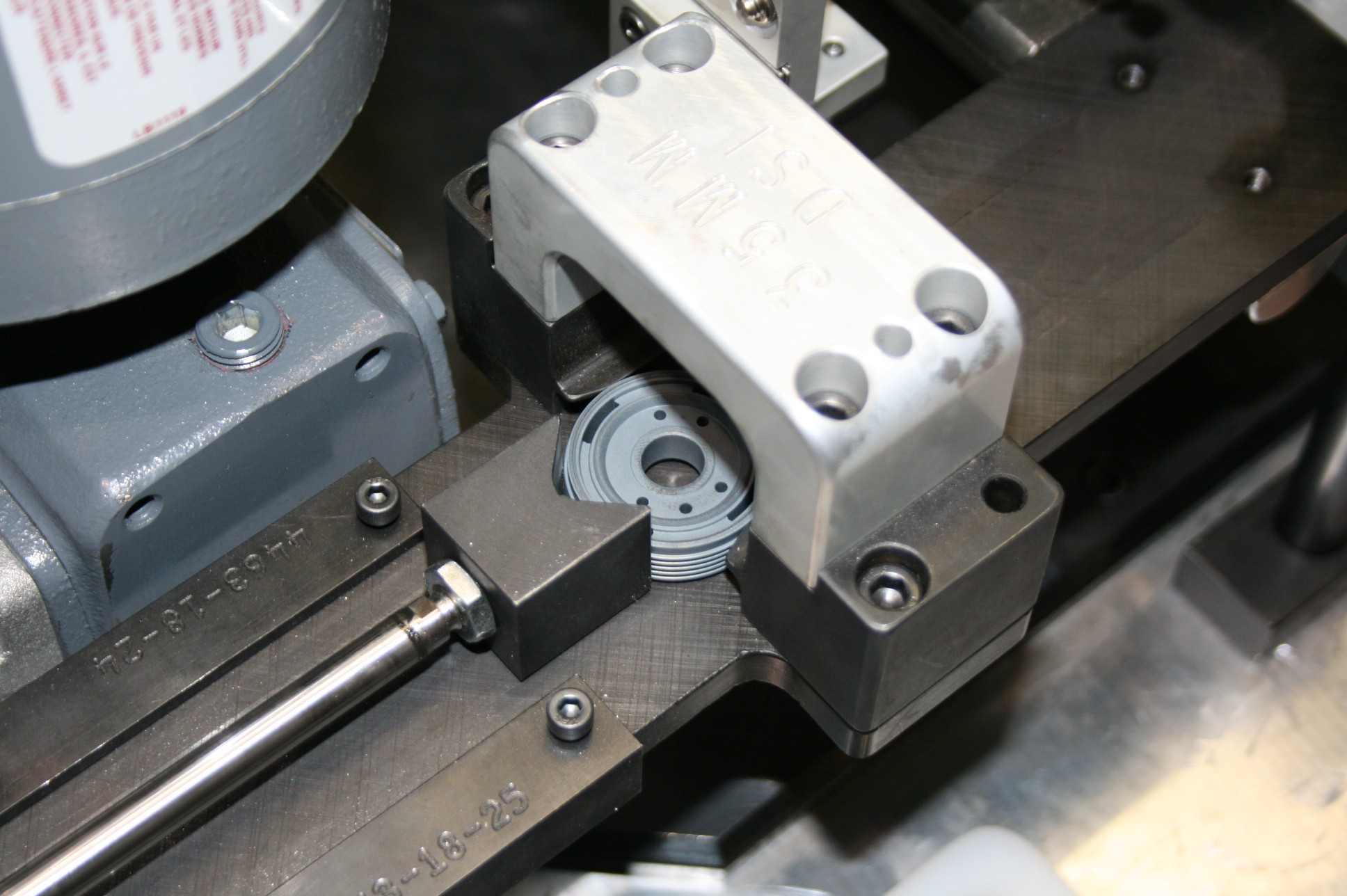

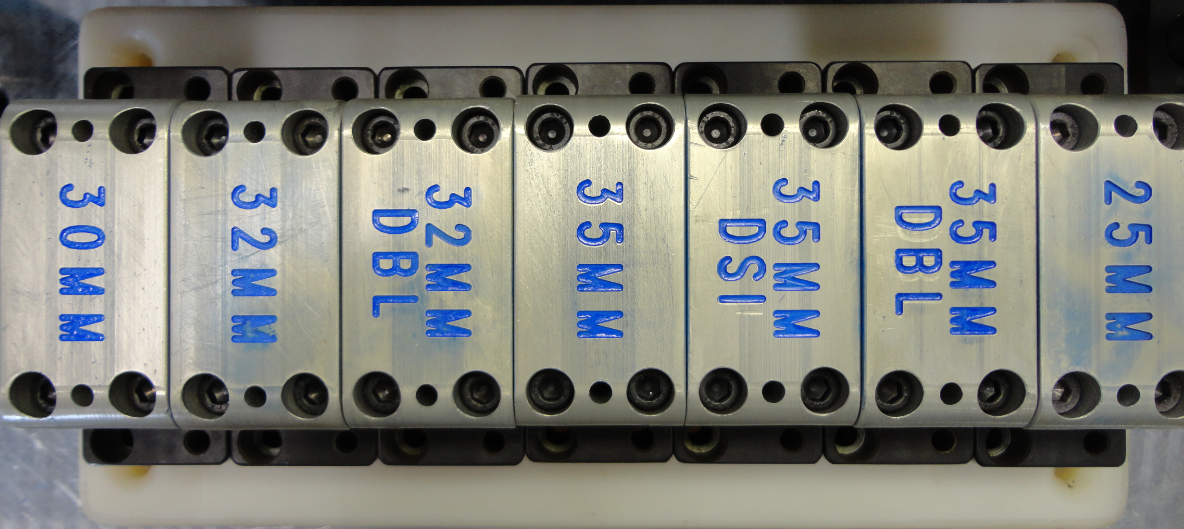

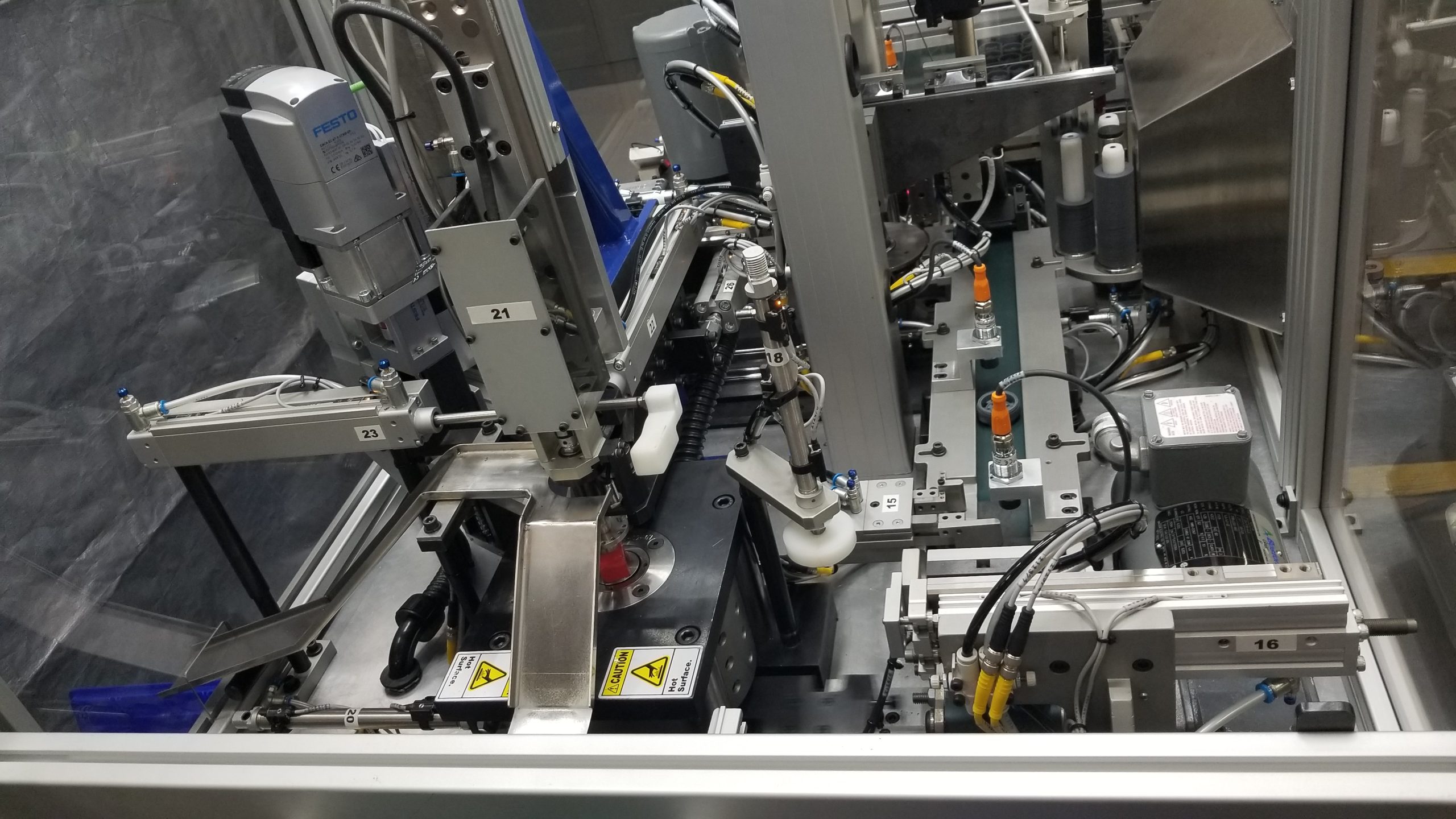

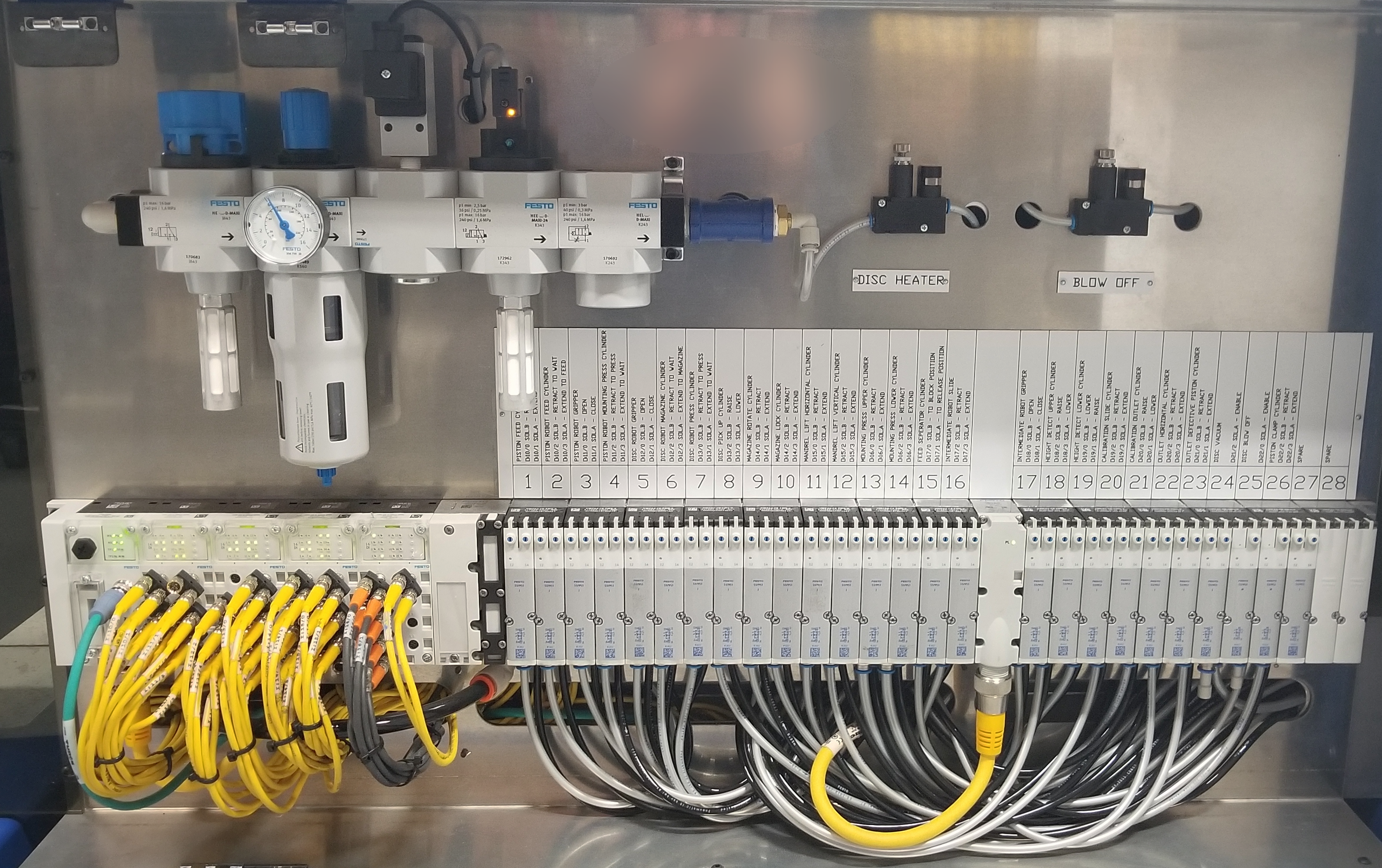

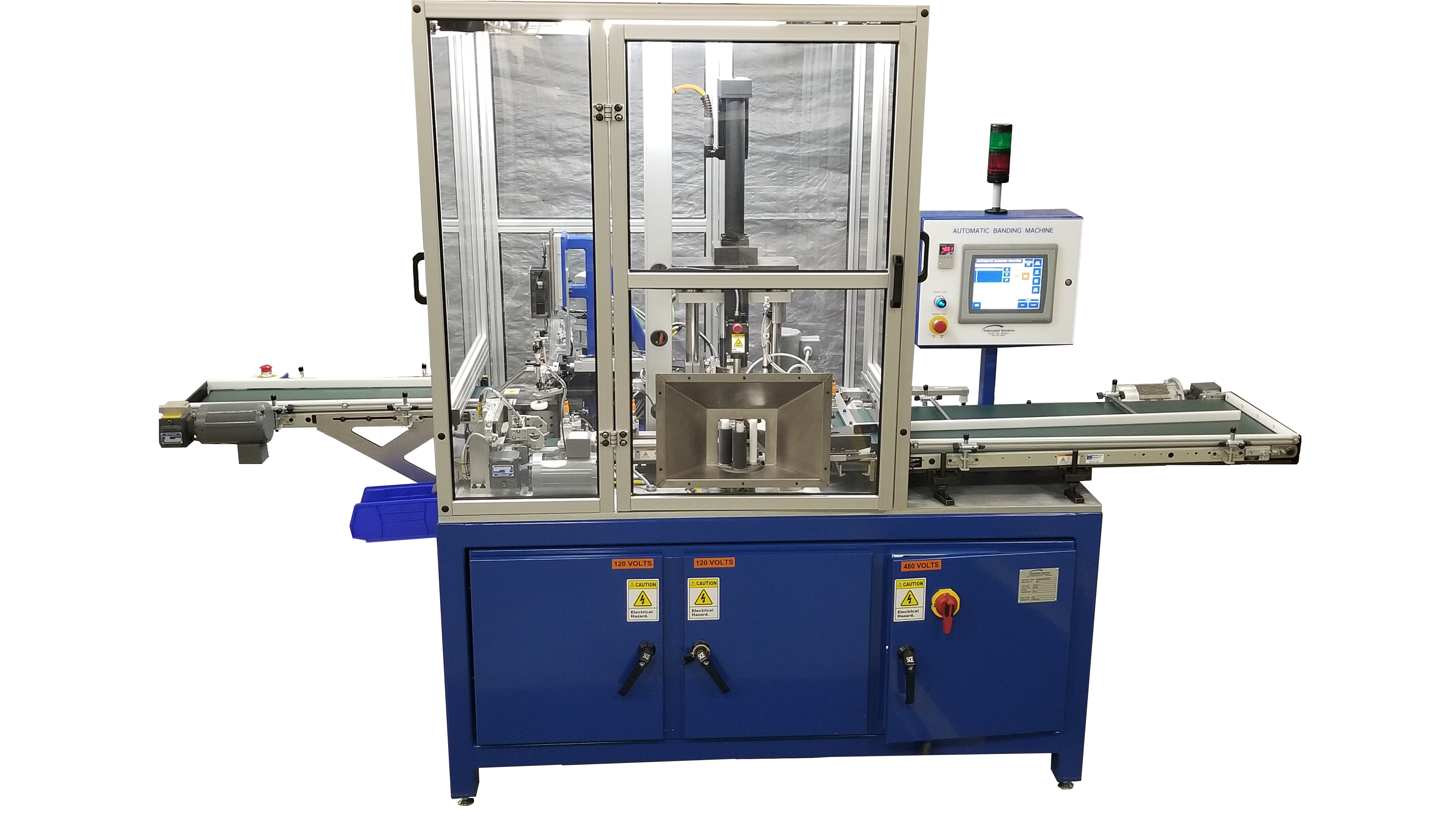

The Automatic Piston Banding Machine is a high-performance, PLC-controlled unit designed to automate the banding process for metal pistons, specifically used in automotive shock absorbers. Equipped with an Allen-Bradley PLC, this machine ensures precise application of PTFE discs onto metal pistons, which are then calibrated to final dimensions through a heated calibration tube. Capable of handling pistons with calibrated diameters ranging from 25 mm to 36 mm, the machine can achieve a typical productivity rate of over 500 parts per hour, making it an efficient solution for high-volume production environments. The integration of servo-electric cylinders for both the band wrapping and piston transportation enhances accuracy and reliability, ensuring consistent results in every cycle.

One of the standout features of the Automatic Piston Banding Machine is its versatility. While it can be dedicated to a specific piston size, the system’s simple tooling changeover allows it to handle multiple piston sizes with ease. This adaptability keeps overall capital equipment costs low, as one machine can be used across different production runs. For manufacturers requiring flexibility, a set of part-specific tools can be exchanged quickly, with changeover times typically around 30 minutes, depending on the operator’s skill level. Additionally, detailed documentation is provided to assist operators with the tooling changeover process, ensuring smooth transitions between different piston sizes.

Safety and operational efficiency are enhanced by the machine’s profile gate system, which is tailored to each unique piston type. These profile gates guarantee that pistons are fed into the press station in the correct orientation, preventing the possibility of banding pistons upside down. If a piston is incorrectly placed, the machine’s gate will detect the issue, causing the system to fault and trigger an alarm on the HMI. Operators can quickly resolve the issue by removing the piston, clearing the fault, and resetting the machine to resume automatic operation. This feature minimizes errors and downtime, ensuring a smooth and reliable production process.

Gallery

Stay up to date with our expert advice and discover how automation can boost efficiency.