Industry-Leading Torque Arm Equipment

Benefits of Torque Arm Systems

Torque reaction arms from Automated Solutions provide numerous operational and ergonomic benefits, including:

Reduction of Torque Reaction: Absorbs torque feedback from fastening tools, protecting operators from injury.

Enhanced Operator Safety: Prevents repetitive strain injuries such as carpal tunnel syndrome.

Reduced Fatigue: Air-balanced systems make tools feel weightless, improving productivity.

Improved Ergonomics: Supports tool weight and facilitates smooth, multi-axis movement.

Spatial Positioning Compatibility: Allows for precision assembly through position feedback integration.

Ease of Use and Design Advantages

Three-Axis Glide: Torque arms glide smoothly across all axes using trolleys or rail systems.

Precision Air Balance: Built-in regulators provide zero-gravity tool support.

Safety Features: Includes safety check valves to prevent tool drops during air loss.

Quick Changeover: Optional quick disconnect pins minimize downtime during tool swaps.

Universal Tool Holders: Standard holders accommodate almost all tool sizes.

Durability: Designed for longevity with minimal preventive maintenance.

Torque Arm Styles and Configurations

Overhead Structure Mount – Online Applications

The most common and versatile reaction arm style, ideal for high-volume assembly lines.

Heavy and light-duty versions available

Mounts to existing overhead structures or a standalone 4-post system

Movement in X, Y, and Z axes

Adjustable travel lengths to suit specific applications

Compatible with spatial positioning systems

Aluminum framework offers high flexibility

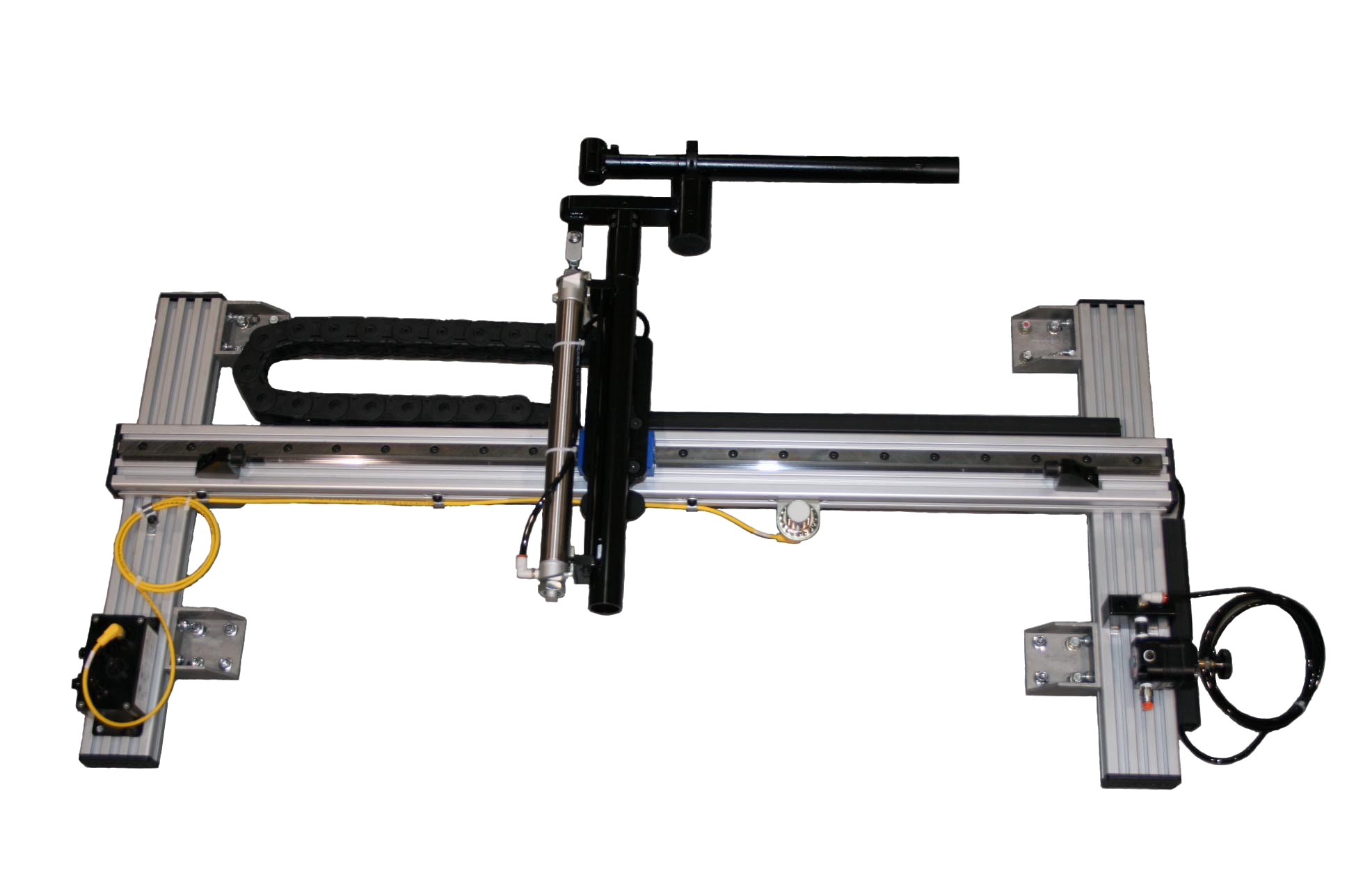

Conveyor/Floor Mount – Online Applications

Designed for environments without overhead structure access.

Mounts to conveyor sides or adjacent floor space

Full three-axis movement and air balancing

Automatic fallback feature prevents tool interference in the line

Available in heavy and light-duty options

Spatial positioning ready

Fixture Integrated – Offline Applications

Tailored for applications requiring torque control as part of fixture-based builds.

Integrated directly into lockout build equipment

Supports spatial positioning

Interfaces with PLC controls for build sequence interlocks

Suitable for electric torque tools and rivet guns

Customizable based on specific tooling needs

Table/Station Mount – Offline Applications

Perfect for prototype or low-volume production settings.

Scissor-style arm design allows wide range of motion

Heavy-duty version requires floor mount

Light-duty version can be table-mounted

Compatible with pneumatic and electric tools

Available in both standard and custom configurations

Spatial Positioning Options

Automated Solutions offers two distinct spatial positioning technologies to error-proof assembly and ensure precise operations.

Discrete Position Sensing

Uses proximity switches for position tracking

Retro-reflective sensors (Z-axis) and inductive sensors (X & Y)

Cost-effective for simple setups with few positions

Easily replaceable via quick disconnect

Transducer Position Sensing

Offers infinite programmable sensing locations

Supports home position programming

Feedback options: 0V–10V analog, 4–20mA current, I/O Link

Best for complex, high-precision applications

Tool Holders and Accessories

Standard Tool Holders

Universal design for virtually any tool size

Optional quick-change pin for fast swaps

Customizable to meet specific mounting needs

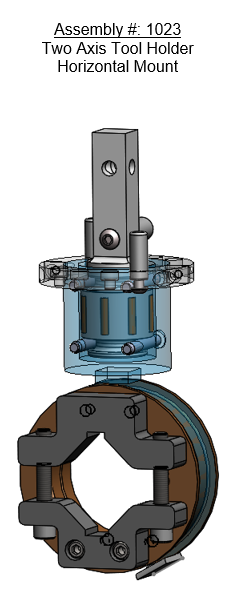

Tool Holder Options

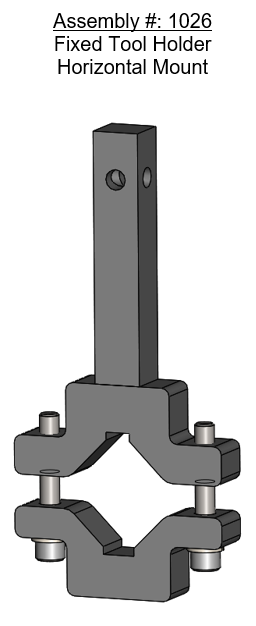

Fixed: Most economical

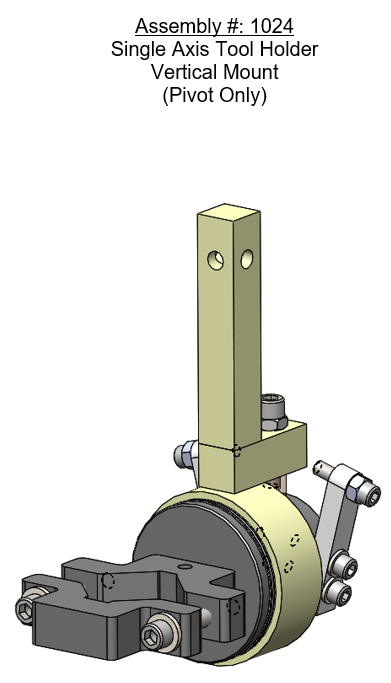

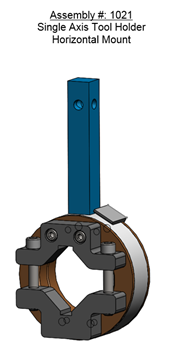

Single Axis: Allows gun axis rotation

Two Axis: Adds vertical axis rotation

Pistol Style: Pivoting for pistol/inline tools

Spare Reaction Arms & I/O Blocks

Spare arms come fully assembled with air cylinder and adapter

Ideal for stations with multiple rows or setups

I/O blocks simplify spatial system wiring and integration

Available in hardwired, I/O Link, and Ethernet configurations

Spare Reaction Arm

I/O Blocks: Call for pricing (varies by manufacturer and setup)

Online Reaction Arm Options

Single Axis Overhead Arm: 16″ vertical, 60″ travel, fore/aft pivot

Two Axis Overhead Arm: Adds 22″ fore/aft travel

Conveyor/Floor Mount Arm: For limited overhead space, 3-axis

Tool Holder

Fixed Horizontal Mount

Single Axis Horizontal Mount

Two Axis Horizontal Mount

Single Axis Vertical Mount