Trim To Foam Clipping machine

Trim Clip Machine

Advanced Seating Assembly for Consistent Quality and Ergonomic Efficiency

In today’s fast-paced manufacturing landscape, quality and consistency are non-negotiable. The Trim Clip Machine from Automated Solutions, Inc. addresses these demands head-on by automating the trim-to-foam assembly process in automotive seating production. Traditionally a manual and labor-intensive operation, this machine enhances throughput, ensures consistent results, and significantly reduces ergonomic risks for operators.

Innovative Patented Technology

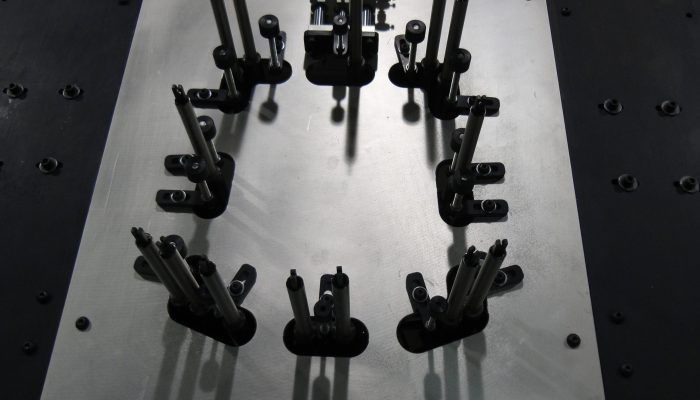

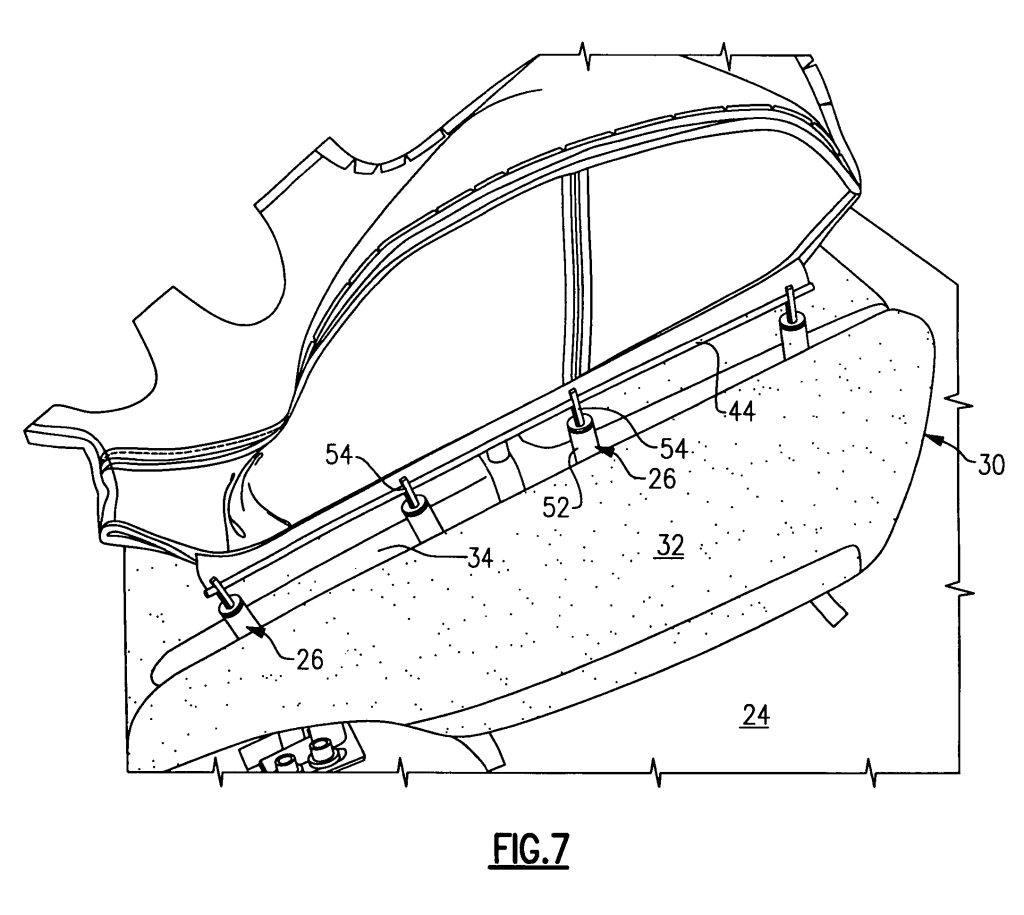

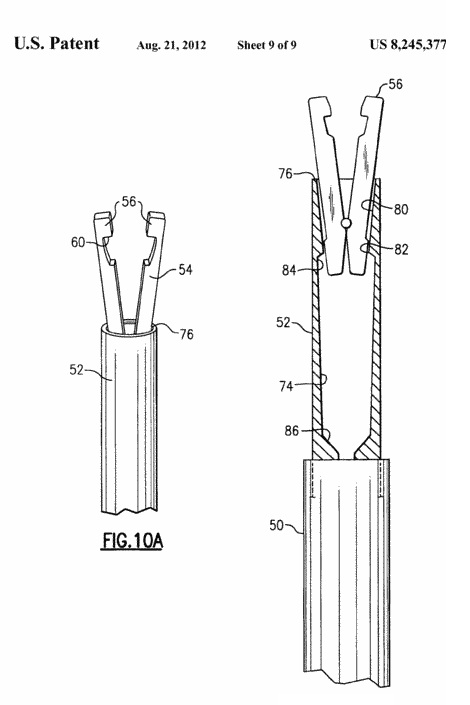

The Trim Clip Machine utilizes a patented mechanism to seamlessly attach seat trim covers to foam buns. Operators load the foam and trim strips onto the machine’s specially designed finger assembly. Upon initiating the cycle, the fingers accurately guide the trim into pre-molded foam clips. This controlled, repeatable process ensures uniform clip engagement without compromising the integrity of the components.

Patents:

US Patent Nos. 8245377, 8375547, 8484821, 9038255

This advanced system improves assembly reliability while minimizing physical strain caused by repetitive motion, a common concern in traditional seat assembly lines.

Simple, Guided Operation

Operator scans the build ticket (if applicable).

Foam is loaded onto the machine’s tooling fingers.

Trim strips are inserted into the finger assembly.

Upon activation, the finger plates retract, pulling the trim into the foam clips.

Once the trim is secured, the fingers reset, and the completed piece is removed.

The entire sequence is streamlined for efficiency and repeatability, making it easy for operators of all skill levels.

Foam Design Considerations

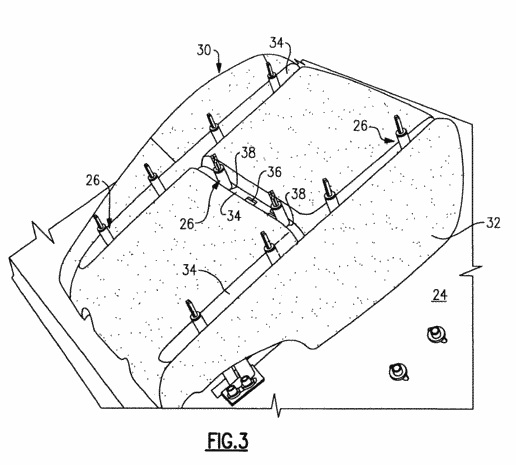

To ensure compatibility with the Trim Clip Machine, foam components must meet specific design criteria:

Embedded plastic clips with adjacent 5/8″ holes for finger access.

25–30mm spacing from clip to hole centerlines.

Minimum 40–50mm spacing between holes to avoid the need for special gripper fingers.

Trim welts should extend slightly beyond the insertion holes for secure placement.

Foam Set onto Fingers

Trim Strips Inserted

Fingers Pull Trim Into Pocket

Screens are welded into the plastic frame, both posts and tabs are used for adhesion. Once welded the plastic posts resemble a rivet or a donut ring.

Stay up to date with our expert advice and discover how automation can boost efficiency.